CLSI EP05-A3 Explained: Your Ultimate Guide to Precision Evaluation in Clinical Method Verification

This comprehensive guide explores the CLSI EP05-A3 guidelines, the definitive standard for evaluating the precision of quantitative measurement procedures in clinical laboratories.

CLSI EP05-A3 Explained: Your Ultimate Guide to Precision Evaluation in Clinical Method Verification

Abstract

This comprehensive guide explores the CLSI EP05-A3 guidelines, the definitive standard for evaluating the precision of quantitative measurement procedures in clinical laboratories. Tailored for researchers, scientists, and drug development professionals, we break down the foundational concepts, step-by-step application methodology, common troubleshooting scenarios, and comparative validation strategies. Learn how to design robust precision studies, interpret complex statistical outputs, optimize assay performance, and ensure regulatory compliance for diagnostic methods and bioanalytical assays in pharmaceutical development.

Understanding EP05-A3: Core Principles and Scope for Precision Studies

The Clinical and Laboratory Standards Institute (CLSI) is a globally recognized organization that develops standards, guidelines, and best practices for medical laboratories. Its mission is to enhance the quality of healthcare testing through the development of evidence-based consensus standards. Among its most critical documents are the Evaluation Protocols (EP) for verifying the performance characteristics of quantitative measurement procedures.

Precision, defined as the closeness of agreement between independent test results obtained under stipulated conditions, is a fundamental metric for assessing the reliability of any clinical assay. Robust precision evaluation is a cornerstone of method validation, ensuring that patient results are consistent, reliable, and suitable for clinical decision-making in drug development and diagnostics.

The Evolution of EP05: From A2 to A3

The CLSI EP05 guideline, titled "Evaluation of Precision of Quantitative Measurement Procedures," is the definitive protocol for precision studies. Its evolution from the second edition (EP05-A2, published in 2004) to the third edition (EP05-A3, published in 2014) represents a significant advancement in statistical rigor and practical applicability.

Core Evolution Summary: The primary shift from EP05-A2 to EP05-A3 is the move from a nested (hierarchical) experimental design to a balanced, multi-day, multi-run, multi-replicate design. EP05-A2 focused on separating components of variance (e.g., between-day, within-day) but its designs could be inefficient and complex to analyze. EP05-A3 advocates for a more straightforward, balanced design that facilitates the use of modern variance component analysis and directly aligns with contemporary quality control concepts like Six Sigma.

The following table summarizes the key quantitative and procedural differences between the two editions.

Table 1: Comparative Summary of CLSI EP05-A2 vs. EP05-A3

| Feature | EP05-A2 (2004) | EP05-A3 (2014) |

|---|---|---|

| Experimental Design | Nested (hierarchical) design. | Balanced design (e.g., 2x2x5 or 2x3x5). |

| Minimum Recommended Days | 20 days for total precision. | 5 days (minimum), with 3-5 runs per day. |

| Replicates per Run | Often 2 replicates. | Typically 5 replicates per run. |

| Primary Analysis Method | Nested ANOVA. | Variance component analysis via ANOVA (balanced data simplifies this). |

| Precision Estimates | Within-run, between-run, between-day, total. | Repeatability, Within-laboratory (Intermediate) Precision. |

| Focus | Detailed separation of all variance components. | Practical estimation of Repeatability and Within-Lab Precision with a simpler protocol. |

| Alignment with Other Standards | Standalone methodology. | Harmonized with CLSI EP15 and ISO 5725 concepts. |

Detailed EP05-A3 Experimental Protocol

The EP05-A3 guideline provides a clear, step-by-step protocol for conducting a precision study. The following is a detailed methodology for a typical study.

Protocol Title: Evaluation of Repeatability and Within-Laboratory Precision per CLSI EP05-A3.

Objective: To estimate the standard deviation (SD) and coefficient of variation (CV) for Repeatability (Sr) and Within-Laboratory Precision (SwL).

Materials: See "The Scientist's Toolkit" section below. Test Samples: A minimum of two concentration levels (normal and pathological) of stable, homogenous material. Each is treated as a separate experiment.

Experimental Workflow:

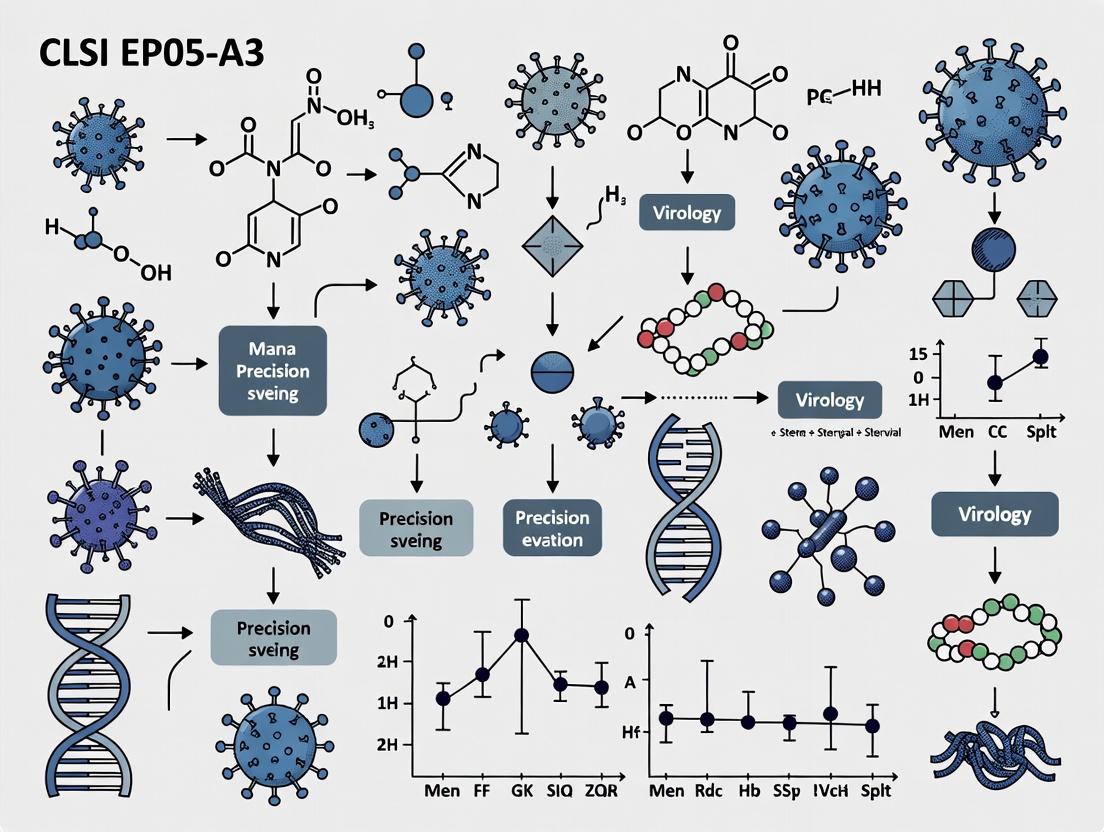

Diagram 1: EP05-A3 Precision Study Workflow (76 chars)

Detailed Steps:

- Design: Select the balanced design pattern:

ddays xrruns/day xnreplicates/run. A common design is 5 days x 2 runs/day x 5 replicates/run, yielding 50 data points per sample level. - Sample Preparation: Aliquot sufficient volume of each test material for all replicates to avoid freeze-thaw cycles.

- Daily Execution: Over 5 non-consecutive days (to capture between-day variability), perform the testing. For each day, initiate a new calibration (if required) and perform

rseparate runs (e.g., morning and afternoon). - Replication: Within each run, assay the test sample

ntimes as independent replicates (not just reading from the same tube). - Data Recording: Organize data in a three-dimensional matrix (Day, Run, Result).

- Statistical Analysis: Perform a variance component analysis using ANOVA on the balanced data.

- Calculate the mean for each run.

- Use the within-run variation to calculate Repeatability Variance (Sr^2).

- Use the between-run and between-day variations to calculate Within-Laboratory Variance (SwL^2).

- Calculation:

- Repeatability SD (Sr) = sqrt(MSwithin) where MSwithin is the mean square from the ANOVA's residual (within-run) component.

- Within-Laboratory SD (SwL) = sqrt(S²run + S²day + S²_within), where S² components are estimated from the ANOVA.

- CV (%) = (SD / Grand Mean) * 100.

- Interpretation: Compare the calculated Sr and SwL (as CV%) to predefined performance goals based on biological variation, regulatory requirements, or manufacturer's claims.

Table 2: Example Data Output from a 5x2x5 EP05-A3 Study

| Sample Level | Grand Mean | Repeatability (Sr) | Repeatability CV% | Within-Lab Precision (SwL) | Within-Lab CV% |

|---|---|---|---|---|---|

| Normal (100 mg/dL) | 101.2 mg/dL | 0.85 mg/dL | 0.84% | 1.52 mg/dL | 1.50% |

| Pathological (350 mg/dL) | 347.5 mg/dL | 3.21 mg/dL | 0.92% | 5.88 mg/dL | 1.69% |

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for CLSI EP05-A3 Precision Studies

| Item | Function & Importance in Precision Studies |

|---|---|

| Commutable, Human-Based QC/Reference Material | Serves as the test sample. Must mimic patient serum matrix to ensure realistic performance evaluation. Critical for accurate precision estimation. |

| Calibrators Traceable to Reference Methods | Ensures the measurement scale is accurate. Precision studies assume a stable calibration; using validated calibrators is foundational. |

| Precision-grade Buffers & Reagents | Consistent lot of assay-specific reagents (enzymes, antibodies, substrates, buffers). Inconsistency introduces unwanted variance, confounding the study. |

| Standardized Diluents & Matrix Solutions | For protocols requiring dilution. Matrix-matched diluents prevent non-linear recovery, which can affect precision at different concentrations. |

| Instrument-Specific Maintenance Kits | Properly maintained instrumentation is a prerequisite. Kits for cuvette cleaning, photometer checks, and pipette calibration ensure the variance measured is assay-related. |

| Statistical Software (e.g., R, SAS, JMP, JASP) | Essential for performing variance component analysis (ANOVA) on balanced data as mandated by EP05-A3. Spreadsheets are insufficient for robust analysis. |

Diagram 2: Logical Flow of EP05-A3 Precision Evaluation (74 chars)

This whitepaper delineates the critical evolution from CLSI EP05-A2 to EP05-A3, underscoring a paradigm shift towards more practical, robust, and statistically transparent precision evaluation. Within the broader thesis on EP05-A3 guidelines research, this analysis establishes the foundational framework. The adoption of the balanced experimental design, as detailed in the protocol and visualized in the workflow, is not merely a procedural change but a strategic enhancement. It directly enables more reliable estimation of variance components that are actionable for laboratory quality management. The "Scientist's Toolkit" further operationalizes this framework, linking high-quality reagents and tools directly to the fidelity of the variance separation process. Consequently, EP05-A3 serves as a superior, harmonized standard, providing drug development professionals and researchers with a more defensible and clinically relevant assessment of assay precision, which is indispensable for ensuring the integrity of data supporting regulatory submissions and patient care.

Within the framework of Clinical and Laboratory Standards Institute (CLSI) EP05-A3 guidelines—Evaluation of Precision of Quantitative Measurement Procedures—precision is a foundational concept for validating the reliability of assays in drug development and clinical research. The EP05-A3 protocol provides a rigorous, statistically driven methodology for estimating the components of measurement procedure precision, namely repeatability, intermediate precision, and reproducibility. This document serves as an in-depth technical guide to these core concepts, framing them within the experimental design and data analysis requirements of EP05-A3, which is critical for researchers and scientists ensuring data integrity in pharmaceutical development.

Core Definitions and Relationships

Precision describes the closeness of agreement between independent test results obtained under stipulated conditions. The hierarchy of precision conditions, as defined by EP05-A3 and ICH Q2(R2), is structured as follows:

1. Repeatability: Precision under a set of identical conditions (same measurement procedure, same operator, same measuring system, same location, and replicate measurements over a short period). This represents the smallest variance component.

2. Intermediate Precision: Precision under conditions that vary within a single laboratory over time (different days, different operators, different equipment). This variance includes repeatability plus additional between-day, between-operator, and between-instrument variances.

3. Reproducibility: Precision under conditions where measurements are made in different laboratories (inter-laboratory study), representing the broadest condition and the largest variance.

The relationship and hierarchy of these components can be visualized as nested variance contributions.

Title: Hierarchy of Precision Components

The following table summarizes the relative magnitude of variance components typically observed in a precision study following an EP05-A3 design for a hypothetical bioanalytical assay.

Table 1: Variance Component Breakdown for a Model Assay

| Precision Component | Source of Variation | Estimated Variance (µg/mL)² | % Contribution to Total Variance | Coefficient of Variation (%CV) |

|---|---|---|---|---|

| Repeatability | Within-run | 0.25 | 16% | 2.5% |

| Intermediate Precision | Between-day | 0.40 | 25% | 3.2% |

| Between-analyst | 0.30 | 19% | 2.8% | |

| Reproducibility | Between-laboratory | 0.65 | 40% | 4.1% |

| Total | All sources | 1.60 | 100% | 5.0% |

Note: Data is illustrative, based on a composite of typical HPLC-UV assay studies. Actual values are method-dependent.

Detailed Experimental Protocols

The CLSI EP05-A3 guideline prescribes a specific experimental design and statistical analysis protocol.

Protocol 1: EP05-A3 Basic Precision Experiment (Repeatability & Intermediate Precision)

- Experimental Design: A nested, balanced design. Test at least two concentration levels (e.g., low and high QC samples). For each level:

- Involve 2 or more operators.

- Analyze the sample in duplicate (two independent measurements) per run.

- Perform one run per day for each operator.

- Repeat this process for 5 to 20 days (EP05 recommends at least 20 days for robust estimates).

- Sample Analysis: Follow the standard validated method for sample preparation, instrument calibration, and measurement.

- Data Collection: Record the individual measurement results for each duplicate.

- Statistical Analysis: Perform a nested analysis of variance (ANOVA) on the data. This model partitions the total variance into components:

- Variance between days.

- Variance between operators (if applicable).

- Variance within a day (repeatability, from the difference between duplicates).

- Calculation:

- Repeatability Standard Deviation (Sr): Calculated from the within-day variance.

- Intermediate Precision Standard Deviation (SIP): Calculated as the square root of the sum of within-day and between-day (and between-operator) variances.

Protocol 2: Inter-Laboratory Study for Reproducibility

- Study Organization: A central coordinating laboratory prepares homogeneous, stable test samples and a detailed, standardized protocol.

- Participant Labs: A minimum of 8 laboratories is recommended. Each lab should have proven competence with the method type.

- Experimental Execution: Each laboratory performs the analysis following Protocol 1 (or a simplified version) over multiple days, using its own analysts, equipment, and reagent lots.

- Data Aggregation & Analysis: The central lab collects all data. A one-way ANOVA is performed with "laboratory" as the single factor.

- Calculation: Reproducibility Standard Deviation (S_R): Calculated as the square root of the sum of the between-laboratory variance and the average within-laboratory (intermediate precision) variance.

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key Materials for Precision Studies per CLSI EP05-A3

| Item | Function in Precision Evaluation |

|---|---|

| Certified Reference Material (CRM) | Provides a metrologically traceable value with defined uncertainty. Serves as the "truth" for assessing accuracy and precision bias. |

| Stable, Homogeneous QC Pools | Patient or matrix-based pools at low, mid, and high concentrations. Used as test samples across the entire study to estimate variance components under actual conditions. |

| Calibrators with Independent Traceability | Separate lot from reagents, used to establish the calibration curve. Ensures variance estimates are not confounded by a single calibrator lot. |

| Matrix-Matched Reagents | Critical for bioanalytical methods. Reagents (e.g., serum, plasma, buffer) must match the sample matrix to avoid interference-related variance. |

| Documented Reagent Lots | All reagent and consumable lots must be recorded. For intermediate precision, intentionally changing lots during the study provides variance data for this factor. |

| Standardized Operational SOPs | Detailed, written procedures for every step (pipetting, incubation, instrument operation) are mandatory to minimize operator-induced variability. |

Visualizing the EP05-A3 Experimental Workflow

The following diagram outlines the step-by-step workflow for conducting a complete precision evaluation from experimental design to final report, as guided by EP05-A3.

Title: EP05-A3 Precision Evaluation Workflow

The rigorous differentiation between repeatability, intermediate precision, and reproducibility is not merely semantic but is essential for understanding and controlling the variability inherent in any quantitative measurement procedure. The CLSI EP05-A3 guideline provides a robust, statistically sound framework for designing experiments and calculating these distinct precision components. For drug development professionals, implementing EP05-A3 is critical for demonstrating assay reliability to regulatory authorities, ensuring that decisions regarding drug safety and efficacy are based on data of known and acceptable quality. Ultimately, defining and quantifying precision at all levels forms the bedrock of credible scientific research in the clinical and pharmaceutical sciences.

This document is a component of a broader thesis exploring the Clinical and Laboratory Standards Institute (CLSI) EP05-A3 guideline, titled "Evaluation of Precision of Quantitative Measurement Procedures." Within the context of method verification in regulated laboratories, EP05-A3 provides the definitive statistical framework for estimating the precision (repeatability and within-laboratory precision) of quantitative measurement procedures. Its application is critical for establishing the reliability of assays in clinical diagnostics, pharmaceutical development, and biotechnology.

Core Scope of CLSI EP05-A3

The primary scope of EP05-A3 is to provide a standardized, statistically rigorous protocol for designing and analyzing a precision experiment. It is specifically designed for use by a single laboratory (often a manufacturer or an end-user lab) to estimate precision parameters that are representative of performance under typical, within-laboratory operating conditions.

Key Definitions:

- Repeatability (s_r): Precision under conditions where independent test results are obtained with the same method on identical test items, by the same operator, using the same equipment within short intervals of time. Formerly "within-run" precision.

- Within-Laboratory Precision (s_wl): The precision of results obtained over an extended period within a single laboratory, incorporating multiple runs, operators, calibrations, and reagent lots. It encompasses both repeatability and between-day/operator variance.

When and Why to Use EP05-A3

| Application Scenario | When to Use EP05-A3 | Primary Rationale |

|---|---|---|

| Laboratory Method Verification | When introducing a new, FDA-cleared/CE-IVD assay to the laboratory's test menu. | To verify that the laboratory's observed precision meets or exceeds the manufacturer's claims and is acceptable for clinical use. |

| In-House Assay Validation | During the development and full validation of a laboratory-developed test (LDT). | To establish foundational performance claims for repeatability and within-laboratory precision as part of the validation dossier. |

| Manufacturer's Claim Support | During the design and development of an in-vitro diagnostic (IVD) device. | To generate precision estimates for inclusion in regulatory submissions (FDA 510(k), PMA, CE Mark technical file). |

| Periodic Performance Review | As part of a laboratory's ongoing quality assurance, typically semi-annually or annually. | To monitor the stability of measurement precision over time and identify potential drift or increased variability. |

| Comparison Studies | When comparing the precision of two different instruments, methods, or reagent lots. | To provide a structured, comparable dataset for statistical comparison (e.g., F-test, t-test). |

The following table summarizes typical precision performance tiers for common analytes, illustrating expected coefficients of variation (CV%) based on EP05-A3 experiments.

| Analyte Category | Example Analytes | Desirable Repeatability CV% | Acceptable Within-Lab CV% | Common Sources |

|---|---|---|---|---|

| Clinical Chemistry | Sodium, Chloride | ≤ 1.5% | ≤ 2.0% | CLIA, RiliBÄK |

| Immunoassay | TSH, Troponin I | ≤ 5.0% | ≤ 10.0% | Manufacturer Claims |

| Therapeutic Drugs | Vancomycin, Digoxin | ≤ 4.0% | ≤ 8.0% | CAP Guidelines |

| Hematology | WBC, Hemoglobin | ≤ 3.0% | ≤ 4.5% | ICSH Guidelines |

| Coagulation | PT (INR), Fibrinogen | ≤ 3.0% | ≤ 5.0% | CLSI H57 |

Detailed Experimental Protocol (EP05-A3 Core Experiment)

The EP05-A3 protocol is a balanced, nested design. The following is a detailed methodology for a standard experiment involving 2 replicates per run, 2 runs per day, over 20 days.

1. Experimental Design & Materials:

- Design: 2 x 2 x 20 nested design (Replicates x Runs x Days).

- Samples: At minimum, three concentration levels (low, medium, high) of stable, commutable control materials or patient pools.

- Duration: 20 to 30 non-consecutive days to capture long-term variability.

2. Daily Protocol:

- Calibration: Perform the laboratory's routine calibration procedure.

- Run 1: In a single, uninterrupted session, analyze two replicates (A1, A2) of each test sample. The replicates should be positioned to detect carry-over or drift within the run.

- Run 2: After a minimum break (e.g., 2 hours, or a new operator shift), repeat Step 2 to obtain replicates B1 and B2. Use a fresh aliquot from the same sample pool.

- Repeat this daily protocol for a total of 20 days, using the same instrumentation and primary reagents, but incorporating expected routine variations (new reagent lots, calibrator lots, and multiple operators as per routine workflow).

3. Data Analysis Workflow:

- Data Logging: Record all results in a format suitable for statistical analysis.

- Variance Component Analysis: Use ANOVA (Nested) to decompose total variance into components:

- Variance between Days (s^2_between-days)

- Variance between Runs within Days (s^2_between-runs)

- Variance between Replicates within Runs (s^2_repeatability)

- Precision Estimation:

- Repeatability Standard Deviation (s_r): sqrt(s^2_repeatability)

- Within-Lab Standard Deviation (s_wl): sqrt(s^2_repeatability + s^2_between-runs + s^2_between-days)

- Express as CV%: (Standard Deviation / Mean of all results) * 100

- Comparison to Goals: Compare calculated CV% to predefined performance specifications (e.g., manufacturer's claims, CLIA limits, biological variation-based goals).

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function in EP05-A3 Study | Critical Considerations |

|---|---|---|

| Commutable Proficiency/Control Material | Serves as the stable test sample across all runs and days. Must mimic patient serum matrix. | Commutability ensures matrix effects are consistent with patient samples. Long-term stability is paramount. |

| Patient-Derived Pooled Serum | An alternative to commercial controls, providing a commutable matrix at clinically relevant levels. | Must be aliquoted and stored frozen at ≤ -70°C to ensure stability over the 20-day study. |

| Calibrators Traceable to Reference Method | Used for routine calibration per standard operating procedure (SOP). | The precision of the calibration process itself contributes to s_wl. Use of different lot numbers during the study is encouraged. |

| Precision-Grade Reagents | The IVD reagent kit or in-house reagents under evaluation. | Introduce at least two different reagent lot numbers during the 20-day study if possible, to capture this source of variance. |

| Internal Quality Control (QC) Materials | Monitors run acceptability; data may be used for supplementary intermediate precision estimates. | Not the primary test sample for EP05-A3, but essential for ensuring each run is in a state of statistical control. |

CLSI EP05-A3 is the cornerstone document for precision estimation in a single laboratory environment. Its structured, nested experimental design and rigorous statistical analysis provide a comprehensive picture of assay variability, encompassing both short-term repeatability and the total within-laboratory precision encountered in real-world practice. Its application is non-negotiable for robust method verification, validation, and ongoing quality monitoring in drug development, clinical research, and diagnostic testing, ensuring that measurement procedures are fit for their intended purpose. This analysis forms a critical chapter in the broader thesis, demonstrating the practical implementation and interpretive power of the EP05-A3 framework.

This whitepaper provides an in-depth technical guide to the core statistical parameters—Standard Deviation (SD), Coefficient of Variation (CV%), Confidence Intervals (CI), and Total Error (TE)—central to precision evaluation in clinical laboratory method validation. The content is framed explicitly within the research context of the Clinical and Laboratory Standards Institute (CLSI) EP05-A3 guideline, Evaluation of Precision of Quantitative Measurement Procedures. Understanding these interlinked concepts is essential for researchers, scientists, and drug development professionals to design robust experiments, interpret validation data correctly, and ensure the reliability of bioanalytical and clinical test results.

Core Terminology and Quantitative Relationships

Definitions and Mathematical Foundations

- Standard Deviation (SD): A measure of the absolute dispersion or variability in a dataset around the mean. It is expressed in the same units as the original data.

- Formula (Sample SD): ( s = \sqrt{\frac{\sum{i=1}^{n}(xi - \bar{x})^2}{n-1}} )

- Coefficient of Variation (CV%): A relative measure of dispersion, calculated as the ratio of the standard deviation to the mean, expressed as a percentage. It allows for comparison of variability across different measurement scales or concentrations.

- Formula: ( CV\% = \left( \frac{s}{\bar{x}} \right) \times 100\% )

- Confidence Interval (CI): A range of values, derived from sample statistics, that is likely to contain the true population parameter (e.g., the true mean or true SD) with a specified level of confidence (e.g., 95%).

- Formula for Mean CI: ( CI = \bar{x} \pm (t_{\alpha/2, df} \times \frac{s}{\sqrt{n}}) )

- Total Error (TE): A single metric that combines systematic error (bias) and random error (imprecision) to describe the overall error likely in a single measurement. It is crucial for setting allowable performance limits.

- Common Formula (based on SD): ( TE = |Bias| + z \times SD ) (where z is often 1.65 for a 95% one-sided interval).

The following table summarizes the key characteristics, uses, and interrelationships of these parameters within an EP05-A3 precision study framework.

Table 1: Core Statistical Parameters in Method Validation

| Parameter | Units | Primary Use in EP05-A3 | Advantage | Limitation | Relationship to Others |

|---|---|---|---|---|---|

| Standard Deviation (SD) | Same as analyte | Quantifying absolute dispersion; calculating ANOVA components for within-run, between-run, and total precision. | Intuitive, foundational for other stats. Absolute value. | Difficult to compare across methods with different means. | Input for CV%, CI, and TE. |

| Coefficient of Variation (CV%) | Percentage (%) | Expressing relative precision; comparing precision at different concentration levels; defining performance goals. | Enables comparison across scales. Unitless. | Can be misleading at very low means. | Derived from SD and Mean. |

| Confidence Interval (CI) | Same as parameter (e.g., % for CV) | Estimating the reliability of precision estimates (e.g., 95% CI for repeatability CV). | Quantifies uncertainty in the estimate. | Wider with smaller sample sizes. | Derived from SD, sample size (n), and t-statistic. |

| Total Error (TE) | Same as analyte or % | Setting acceptability criteria; assessing whether a method's combined error meets clinical requirements. | Holistic view of method performance. | Different models exist (e.g., ±1.65SD vs. root-mean-square). | Combines SD (random error) and Bias (systematic error). |

Experimental Protocols for Precision Evaluation (EP05-A3)

A core tenet of CLSI EP05-A3 is the structured evaluation of precision through a nested experimental design. Below is a detailed methodology for a typical experiment.

Protocol: Nested Precision Evaluation Experiment

1. Objective: To estimate the within-laboratory precision components of a quantitative measurement procedure, including within-run repeatability, between-run, between-day, and total precision.

2. Experimental Design:

- Materials: A single, stable test sample at two clinically relevant concentrations (e.g., low and high).

- Replication Scheme: Perform 2 runs per day, at least 2 hours apart. Within each run, perform duplicate measurements (n=2). Repeat this process for 5 days.

- Total Measurements: 2 concentrations x 5 days x 2 runs/day x 2 replicates/run = 40 data points.

3. Procedure:

- Calibrate the analytical system according to the manufacturer's protocol.

- On Day 1, prepare the test sample. Perform the first run (Run 1), analyzing the sample in duplicate. Record both results.

- After a minimum 2-hour interval, perform a second independent run (Run 2) with fresh reagents/calibration if required, analyzing the sample in duplicate again.

- Repeat Steps 2-3 on Days 2 through 5, ensuring sample stability is maintained.

- Repeat the entire protocol for a second concentration level.

4. Statistical Analysis (Nested ANOVA):

- Enter data into a statistical software package capable of nested ANOVA.

- For each concentration level, perform a nested ANOVA with factors: Day (random), Run within Day (random), and Replicate within Run.

- Extract Variance Components:

- Variance between Replicates = Within-run variance (S²r).

- Variance between Runs (within Days) = Between-run variance (S²R).

- Variance between Days = Between-day variance (S²_D).

- Calculate Precision Estimates:

- Repeatability SD (Sr): ( Sr = \sqrt{S²r} )

- Within-Lab/Between-Run SD (SR): ( SR = \sqrt{S²r + S²R} )

- Total Precision SD (ST): ( ST = \sqrt{S²r + S²R + S²D} )

- Calculate corresponding CV% for each SD (CV = SD/Mean * 100%).

- Calculate 95% Confidence Intervals for each variance component and CV estimate.

Visualization of Concepts and Workflow

Diagram 1: Relationship of Statistical Parameters in Error Analysis

Diagram 2: EP05-A3 Nested Experiment Workflow & Analysis

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Materials for CLSI EP05-A3 Precision Studies

| Item | Function / Purpose | Critical Considerations |

|---|---|---|

| Stable, Commutable Control Material or Pooled Patient Sample | Serves as the test sample for repeated measurements. Must mimic patient matrix. | Stability over the study period is paramount. Should be at medically relevant concentrations (e.g., low, mid, high). |

| Calibrators | Used to establish the analytical measurement scale (calibration curve). | Must be traceable to a higher-order reference. Calibration interval must be defined per protocol. |

| Quality Control (QC) Materials | Used to monitor system performance independently from the test sample. Not the primary test sample for EP05. | Should be run at beginning/end of runs to verify system stability throughout the experiment. |

| Matrix-matched Diluent | For potential sample dilution to maintain linearity and matrix effects. | Should match the sample matrix (e.g., human serum) to avoid dilution-induced error. |

| Primary Reagent Kit | The core chemistry/immunoassay reagents for the analyte of interest. | Use a single, consistent lot number throughout the entire precision study to isolate variance sources. |

| Consumables (Cuvettes, Pipette Tips, Microplates) | Standardized vessels for reaction and measurement. | Use the same brand and lot throughout the study to minimize consumable-induced variability. |

| Data Collection & Statistical Software | For recording raw data and performing nested ANOVA/variance component analysis. | Software must be validated for its intended use. Familiarity with nested statistical models is required. |

Within the broader thesis on CLSI EP05-A3 precision evaluation guidelines research, a critical analysis of its alignment with global regulatory frameworks is essential. EP05-A3, Evaluation of Precision of Quantitative Measurement Procedures, provides the foundational statistical methodology for establishing the precision performance of in vitro diagnostic (IVD) assays and clinical laboratory methods. This whitepaper provides an in-depth technical guide on how EP05-A3’s principles and experimental designs align with, and are referenced by, key regulatory guidance from the U.S. Food and Drug Administration (FDA), the European Medicines Agency (EMA), and the International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH).

Core Regulatory Guidelines and Their Precision Requirements

The table below summarizes the primary regulatory documents and their specific precision-related expectations that EP05-A3 helps to address.

Table 1: Key Regulatory Guidelines and Precision Parameters

| Regulatory Body | Guideline Number/Title | Key Precision Parameters Addressed | EP05-A3 Alignment |

|---|---|---|---|

| FDA (U.S.) | Bioanalytical Method Validation Guidance for Industry (May 2018) | Within-run (repeatability), Between-run, Total imprecision. Acceptance: ≤15% CV (20% at LLOQ). | EP05-A3 provides the rigorous experimental design (nested ANOVA) to estimate these variance components separately. |

| EMA (EU) | Guideline on bioanalytical method validation (2011, effective 2012) | Repeatability, Intermediate precision, Reproducibility. Acceptance: ≤15% CV (20% at LLOQ). | EP05-A3's multi-day, multi-replicate protocol directly estimates repeatability and intermediate precision. |

| ICH | ICH Q2(R2) Validation of analytical procedures (2023, Final) | Repeatability, Intermediate Precision (Ruggedness). Defines experimental requirements. | EP05-A3 is a recognized standard methodology for conducting these precision studies as per Q2(R2). |

| FDA & CMS | Statistical Guidance on Reporting Results from Studies Evaluating Diagnostic Tests | Imprecision estimates (standard errors, confidence intervals). | EP05-A3 mandates robust statistical analysis and CI reporting for all precision estimates. |

Detailed Experimental Protocol from EP05-A3

The following methodology is the core protocol recommended by CLSI EP05-A3 to generate data compliant with FDA, EMA, and ICH expectations.

Protocol: EP05-A3 Precision Evaluation Experiment

Objective: To estimate the repeatability (within-run), within-laboratory (intermediate) precision, and total imprecision of a quantitative measurement procedure.

Experimental Design:

- A minimum of 2 replicates per sample per run.

- A minimum of 1 run per day.

- A minimum of 5 days (recommended 20 days for robust intermediate precision estimation).

- Test a minimum of 2 concentration levels (normal and abnormal pathological range).

- All testing must be performed by a single operator using one lot of reagents and calibrators on a single instrument, unless specifically testing these as factors.

Procedure:

- Calibrate the instrument according to the manufacturer's instructions at the beginning of the study and as required per routine schedule.

- For each day of testing (

d = 1 to D), perform one analytical run. - Within each run, analyze each test sample (

k = 1 to K) in duplicate (n = 2), in random order to avoid systematic bias. - Maintain routine quality control procedures throughout the study. Data from runs failing QC must be investigated and potentially excluded.

Statistical Analysis (Nested ANOVA):

- The data structure (Days > Runs > Replicates) is analyzed using nested analysis of variance.

- Key calculations:

- Repeatability Variance (Sr^2): Variance among replicates within the same run.

- Between-Day Variance (Sd^2): Variance due to differences between days.

- Within-Laboratory (Intermediate) Precision Variance (SI^2): SI^2 = Sr^2 + Sd^2

- Report estimates as standard deviation (SD) and coefficient of variation (CV%), with 95% confidence intervals.

Alignment and Compliance Pathways

The following diagram illustrates the logical flow from the EP05-A3 experiment to meeting specific regulatory requirements.

Diagram 1: From EP05-A3 to Regulatory Compliance

The Scientist's Toolkit: Key Research Reagent Solutions

Successful execution of an EP05-A3-compliant precision study requires carefully characterized materials. The following table details essential components.

Table 2: Essential Materials for EP05-A3 Precision Studies

| Item | Function in Precision Evaluation | Critical Considerations |

|---|---|---|

| Commutable Proficiency/QC Material | Serves as the stable, consistent sample tested across all days and runs. | Should mimic patient sample matrix, be stable for study duration, and target clinically relevant concentrations. |

| Frozen Patient Pools | Provides a true biological matrix for evaluation at specific medical decision points. | Must be aliquoted properly to avoid freeze-thaw variability. Homogeneity is critical. |

| Instrument-Specific Calibrators | Ensures the measurement procedure is traceable to a reference, maintaining accuracy baseline. | Use same lot throughout study. Calibration frequency must follow protocol. |

| Liquid QC Materials | For daily monitoring of assay stability and performance during the study period. | Should be run at beginning and end of each run to accept run data. |

| Primary Reference Material (if applicable) | For methods establishing traceability, used to set calibration. | Sourced from NIST, JCTLM-listed providers, or equivalent. |

Advanced Statistical Output and Data Presentation

The nested ANOVA yields a structured data table suitable for regulatory submission. The example below uses simulated data for a glucose assay at a pathological high level.

Table 3: Example Precision Estimates from a 5-Day EP05-A3 Study (Glucose, ~300 mg/dL)

| Variance Component | Estimate (Variance) | Standard Deviation (SD) | CV% | 95% CI for CV% |

|---|---|---|---|---|

| Repeatability (Within-Run) | 4.92 | 2.22 mg/dL | 0.74% | (0.55%, 1.20%) |

| Between-Day | 7.33 | 2.71 mg/dL | 0.90% | (0.51%, 2.51%)* |

| Within-Lab (Intermediate) Precision | 12.25 | 3.50 mg/dL | 1.17% | (0.79%, 2.13%) |

Note: CI for between-day component is wide due to low degrees of freedom (only 4 days). EP05-A3 recommends 20+ days for a reliable estimate.

The workflow for data processing, from raw results to final report, is systematic.

Diagram 2: Precision Data Analysis Workflow

CLSI EP05-A3 is not an isolated laboratory protocol; it is a regulatory enabler. Its rigorous, statistically sound framework for precision evaluation provides the direct experimental and analytical evidence required to satisfy the explicit demands of FDA, EMA, and ICH guidelines. By implementing the EP05-A3 protocol with high-quality materials, researchers generate defensible data that forms a critical pillar of method validation dossiers, investigational device exemptions (IDEs), and marketing authorization applications (MAAs), thereby bridging the gap between laboratory research and global regulatory compliance.

Step-by-Step Protocol: Designing and Executing an EP05-A3 Precision Study

This technical guide provides an in-depth examination of the core principles of study design within the specific context of research on the Clinical and Laboratory Standards Institute (CLSI) EP05-A3 guideline, Evaluation of Precision of Quantitative Measurement Procedures. This guideline establishes the framework for determining the precision performance of clinical laboratory assays, a critical component of method validation. The fundamentals discussed herein—sample selection, concentration levels, and replication scheme—are the pillars upon which reliable, compliant, and actionable precision estimates are built. Proper application of these fundamentals is essential for researchers, scientists, and professionals in drug development and diagnostic manufacturing to generate data that supports regulatory submissions and ensures clinical utility.

Foundational Principles from CLSI EP05-A3

The CLSI EP05-A3 guideline provides a structured experimental protocol for estimating the precision of a quantitative measurement procedure. Its core objective is to separate and quantify the different components of measurement variability: within-run, between-run, between-day, and total precision. The standard design involves testing multiple samples at defined concentrations across multiple runs and days with structured replication.

Core Study Design Fundamentals

Sample Selection

Sample selection is the first critical decision point. The samples must be representative of the clinical matrix for which the assay is intended (e.g., human serum, plasma, urine). Key considerations include:

- Stability: Samples must remain stable throughout the entire testing period to avoid confounding precision estimates with analyte degradation.

- Commutable: Ideally, samples should behave like fresh patient specimens with respect to the measurement procedure.

- Source: Pooled patient samples are preferred. Commercial quality control materials or processed samples may be used but must be validated for commutability.

- Homogeneity: The sample pool must be thoroughly mixed and aliquoted to ensure minimal vial-to-vial variation, which would be erroneously captured as imprecision.

Concentration Levels

Precision is often concentration-dependent. EP05-A3 mandates testing at a minimum of two concentration levels to characterize this relationship.

- Medical Relevance: Levels should bracket clinically relevant decision points (e.g., low, normal, and high pathological ranges).

- Assay Range: One level should be near the lower end of the reportable range and another near the upper end to assess performance across the assay's dynamic range.

- Number of Levels: While two is the minimum, a third, intermediate level is often recommended for a more robust characterization.

Table 1: Recommended Concentration Level Strategy

| Level | Recommended Position | Purpose |

|---|---|---|

| Level 1 | Near lower limit of quantification (LLoQ) | Evaluates precision where variability is often highest. |

| Level 2 | Within normal physiological range | Assesses precision for typical patient results. |

| Level 3 | Near upper limit of quantification (ULoQ) | Evaluates precision at high analyte concentrations. |

Replication Scheme

The replication scheme defines the data collection structure to partition variance components. The classic EP05-A3 design is a nested (hierarchical) design.

- Basic Structure: Test each concentration level over 5 days, with 2 runs per day, and 2 replicates per run.

- Total Replicates: This yields 20 measurements per concentration level (5 days × 2 runs/day × 2 replicates/run = 20).

- Variance Components: This structure allows for the statistical separation of variance attributable to between-day, between-run (within-day), and within-run sources.

Table 2: Standard EP05-A3 Replication Scheme (Nested Design)

| Factor | Levels | Data Points per Concentration | Variance Component Estimated |

|---|---|---|---|

| Days | 5 | -- | Between-Day (σ²_Day) |

| Runs per Day | 2 | 10 runs total | Between-Run (Within-Day) (σ²_Run) |

| Replicates per Run | 2 | 20 results total | Within-Run (σ²_Within) |

| Total Results | 20 | Total Precision (σ²_Total) |

Detailed Experimental Protocol

The following methodology is prescribed by CLSI EP05-A3 for a full precision evaluation.

Title: Protocol for EP05-A3-Compliant Precision Evaluation Experiment

Objective: To estimate within-run, between-run, between-day, and total standard deviations for a quantitative measurement procedure at two or more concentration levels.

Materials: See "The Scientist's Toolkit" section.

Pre-experimental Phase:

- Sample Preparation: Prepare a homogeneous pool of the appropriate matrix containing the analyte at the target concentration. Aliquot into a sufficient number of identical vials for the entire study. Store aliquots under validated conditions to ensure stability.

- Calibration: Perform a full calibration of the measurement system as per the manufacturer's instructions. Do not re-calibrate between runs unless it is part of the standard operating procedure (SOP).

- Operator Training: Ensure all operators are trained and competent on the SOP.

Experimental Execution:

- For each of the 5 days: a. Remove the required number of sample aliquots from stable storage and allow them to reach testing temperature. b. Perform Run 1: Analyze 2 replicates of each concentration level in a single batch. The replicates should be positioned to assess within-run drift (e.g., at the beginning and end of the run). c. Perform Run 2: At least 2 hours after Run 1, or as a separate batch, analyze another 2 replicates of each concentration level. d. Record all results with run, day, and replicate identifiers.

Data Analysis:

- For each concentration level, perform a nested analysis of variance (ANOVA).

- Calculate the variance components:

- Within-Run Variance (MS_Within)

- Between-Run Variance = (MSRun - MSWithin) / n' (where n' is the number of replicates per run)

- Between-Day Variance = (MSDay - MSRun) / n'' (where n'' is the number of runs per day × replicates per run)

- Compute standard deviations by taking the square root of each variance component.

- Calculate Total Variance: σ²Total = σ²Day + σ²Run + σ²Within.

- Report within-run, between-run, between-day, and total standard deviation and coefficient of variation (%CV).

Visualizing the Study Design and Analysis Workflow

Title: EP05-A3 Precision Evaluation Workflow

Title: Variance Components Sum to Total Precision

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions & Materials for EP05-A3 Studies

| Item | Function & Importance |

|---|---|

| Commutable Human Serum/Plasma Pools | The ideal sample matrix. Pooled from multiple donors to ensure homogeneity and representativeness of clinical samples. Must be characterized for analyte concentration and stability. |

| Certified Reference Materials (CRMs) | Used for target value assignment to sample pools or for verifying calibration traceability during the study. |

| Liquid-Stable or Lyophilized QC Materials | Often used as a practical alternative to patient pools. Critical to verify commutability if used as the primary test sample. |

| Matrix-Specific Diluent or Buffer | For preparing samples at specific concentration levels from a stock pool via dilution, while maintaining matrix integrity. |

| Calibrators Traceable to a Higher Order Standard | Essential for establishing the measurement scale. The precision study is performed on a calibrated system. |

| System Suitability or Reagent Blank Solutions | Used to verify instrument and reagent performance meets specifications before initiating study runs. |

| Stable Storage Vials & Labels | For aliquotting sample pools to ensure identical test portions and prevent vial-to-vial variability. |

| Data Collection Template (Electronic Lab Notebook) | Structured template to record result, run ID, day, replicate number, and operator to ensure data integrity for ANOVA. |

Within the framework of research into Clinical and Laboratory Standards Institute (CLSI) EP05-A3 guidelines, the selection of an appropriate experimental model is critical for robust precision evaluation. EP05-A3, titled "Evaluation of Precision of Quantitative Measurement Procedures," provides the statistical methodology for estimating precision performance. A core decision involves choosing between two primary experimental designs: the 5x5 (or 5x2x5) model and the 5x2 model. This guide details the protocols, data analysis, and application of these models in pharmaceutical and clinical research settings.

Core Experimental Designs

EP05-A3 outlines structured protocols to estimate within-laboratory precision, encompassing repeatability, within-device/batch variability, and between-day variability.

The 5x5 Model (Extended Design)

This comprehensive model involves testing two levels of controls or patient samples over five days, with five replicates per day per level.

Protocol:

- Select two concentrations of material (e.g., one normal, one abnormal).

- For 5 consecutive days, analyze each material in a run of 5 replicate measurements.

- The runs should be performed under conditions that capture routine laboratory variability (different operators, recalibrations).

- Record all data for analysis of variance (ANOVA) calculation.

The 5x2 Model (Abbreviated Design)

This streamlined model is used for a preliminary or less resource-intensive assessment, involving two replicates per day over five days.

Protocol:

- Select two concentrations of material.

- For 5 consecutive days, analyze each material in duplicate (2 replicates) within a single run.

- Ensure runs reflect typical daily operational conditions.

- Record data for nested ANOVA calculation.

Table 1: Comparison of EP05-A3 Experimental Models

| Feature | 5x5 Model (5 days x 5 replicates) | 5x2 Model (5 days x 2 replicates) |

|---|---|---|

| Total Tests per Level | 25 | 10 |

| Primary Estimate | Robust within-laboratory precision (Swr) | Intermediate precision (primarily day-to-day) |

| Statistical Power | High; provides separate estimates for repeatability (Sr) and between-day (Sbetween-day) | Moderate; estimates combined intermediate precision |

| Resource Intensity | High (time, reagents, samples) | Low |

| CLSI Recommendation | Preferred for definitive precision claims | Suitable for feasibility, verification, or when sample volume is limited |

| Key Output Metrics | Sr, Sbetween-day, Swr | Sintermediate |

Table 2: Example ANOVA Output Data Structure (5x5 Model)

| Variance Component | Symbol | Calculation Source | Estimates... |

|---|---|---|---|

| Repeatability | Sr | Mean square within-groups (MSwithin) | Variability within a single run/day |

| Between-Day | Sbetween-day | (MSbetween - MSwithin)/n | Variability from day-to-day factors |

| Within-Lab Precision | Swr | sqrt(Sr2 + Sbetween-day2) | Total internal precision |

Detailed Methodologies

Protocol for the 5x5 Design

- Material Preparation: Acquire two stable, commutable control materials or pooled patient samples at medically relevant concentrations (Level 1 & Level 2). Validate stability over the 5-day period.

- Instrumentation: Use the measurement procedure (assay, analyzer) as defined in the standard operating procedure.

- Daily Run Execution: Each day, perform a new calibration per manufacturer guidelines. Process one run containing 5 replicate measurements of Level 1 and 5 replicate measurements of Level 2 in random order to avoid systematic bias.

- Data Collection: Log results with date, run ID, operator, reagent lot, and calibrator lot.

- Statistical Analysis: Perform a nested ANOVA for each material level separately to partition variance components.

Protocol for the 5x2 Design

- Material Preparation: Same as 5x5 design.

- Daily Run Execution: Each day, perform a single run containing 2 replicate measurements of each level.

- Data Collection: Log results with same metadata as 5x5 design.

- Statistical Analysis: Perform a nested ANOVA or use the CLSI-recommended calculations for the standard deviation of duplicates across days to estimate intermediate precision.

Visualized Workflows

Diagram 1: EP05-A3 Model Selection and Workflow

Diagram 2: Data Structure of 5x5 vs 5x2 Models

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for EP05-A3 Precision Studies

| Item | Function in EP05-A3 Study | Key Considerations |

|---|---|---|

| Commutable Control Materials | Stable, matrix-matched samples at defined concentrations used as test subjects across all runs. | Must mimic patient samples; two distinct concentration levels required; stability over study duration is critical. |

| Calibrators | Used to standardize the measurement system at the start of each day or as per protocol. | Consistent lot usage throughout study or documentation of lot changes is mandatory for variance attribution. |

| Reagent Kits | The measurement procedure's core chemistry/immunoassay components. | A single reagent lot should be used for the entire study to isolate other variance components. If lot change is unavoidable, it becomes a study variable. |

| Quality Control (QC) Pools | Independent materials run to verify system stability during the study, though not the primary data source. | Used for process verification; helps distinguish routine drift from experimental error. |

| Statistical Software | To perform nested ANOVA and calculate variance components (Sr, Sbetween-day, Swr). | Must be capable of hierarchical analysis. Spreadsheets with built-in functions or dedicated packages (R, SAS, CLSI-approved tools) are used. |

The 5x5 and 5x2 models under CLSI EP05-A3 provide a rigorous, statistically sound framework for evaluating the precision of quantitative assays. The 5x5 design remains the gold standard for comprehensive precision claims in drug development and diagnostic validation, offering detailed variance component analysis. The 5x2 design serves as a practical, resource-efficient alternative for preliminary assessments or verification studies. The choice hinges on the study's objective, required statistical power, and available resources, ensuring that precision estimates are both accurate and fit for regulatory and clinical purpose.

Effective data collection is foundational to robust analytical precision evaluation as mandated by the Clinical and Laboratory Standards Institute (CLSI) EP05-A3 guideline. This guideline emphasizes the estimation of measurement imprecision through carefully designed experiments. This whitepaper details best practices for structuring the primary instrument of this process: the data collection spreadsheet. Proper organization ensures data integrity, supports statistical analysis for precision estimates (e.g., repeatability, within-laboratory precision), and provides the audit trail required for regulatory compliance in drug development.

Foundational Spreadsheet Architecture

Core Structural Principles

The spreadsheet should be a direct reflection of the experimental protocol derived from EP05-A3. Key design pillars include:

- Single Source of Truth: One master file or linked system containing all raw data, metadata, and calculations.

- Flat File Structure: Data should be organized in a rectangular, single-table format suitable for statistical software import.

- Human and Machine Readable: Clear labeling for users and consistent formatting for parsing by analysis tools (e.g., R, SAS, JMP).

- Version Control: Clear naming and change-logging to track revisions.

Essential Worksheet Structure

A comprehensive data collection workbook should consist of the following segregated worksheets:

1. Metadata & Protocol 2. RawData 3. Calculations 4. SummaryStatistics 5. Change_Log

Detailed Column-Level Organization for Raw Data

The Raw_Data sheet is the critical component. Each column must have a single, clear purpose.

Table 1: Essential Columns for an EP05-A3 Precision Experiment Spreadsheet

| Column Header | Data Type | Example Entry | Purpose & Traceability Link |

|---|---|---|---|

| Experiment_ID | Text | EP05-2023-001 | Unique identifier linking to the protocol document. |

| Analyst | Text | JDOE | Person responsible for data entry/collection. |

| Date | ISO 8601 (YYYY-MM-DD) | 2023-10-27 | Date of analysis run. |

| Time | 24-hr Format (HH:MM) | 14:30 | Start time of the run. |

| Instrument_ID | Text | LCMS-003 | Unique identifier for the instrument used. |

| Reagent_Lot | Text | CAL-AB123 | Lot number of the calibrator or critical reagent. |

| Sample_ID | Text | QC_L | Identifier for the test sample (e.g., QC level). |

| Sample_Type | Text | Quality Control | E.g., Patient, QC, Calibrator, Blank. |

| Replicate | Integer | 1, 2, 3 | The sequential replicate number within a run/day. |

| Run | Integer | 1, 2 | The independent analytical run (EP05: 2 runs/day). |

| Day | Integer | 1, 2... 20 | The day of testing (EP05: 20 days minimum). |

| Measured_Value | Number | 45.78 | The raw analytical response (e.g., peak area, concentration). |

| Unit | Text | mg/dL | The unit of the measured value. |

| Comment | Text | Sample carryover suspected | For documenting deviations or observations. |

Experimental Protocol: Implementing EP05-A3 in Spreadsheet Design

Methodology for a Typical EP05-A3 Precision Experiment

The following protocol dictates the structure of the data collection spreadsheet.

1. Objective: To estimate the repeatability (within-run imprecision) and within-laboratory imprecision of an analytical method.

2. Experimental Design:

- Materials: Two quality control (QC) materials (low and high concentration), the validated assay method, and the designated instrument.

- Replication Scheme: Over a minimum of 20 days, perform 2 independent analytical runs per day. Within each run, analyze each QC level in duplicate (i.e., two separate aliquots).

- Randomization: The order of QC levels and replicates within a run should be randomized to avoid systematic bias.

3. Data Collection Procedure:

1. Prepare a fresh Raw_Data spreadsheet with columns as defined in Table 1.

2. Prior to daily runs, populate static metadata (ExperimentID, Analyst, InstrumentID, ReagentLot, SampleIDs).

3. For each aliquot measured, create a new row. Record Date, Time, Replicate (1 or 2), Run (1 or 2), Day number, and the Measured_Value.

4. Enter any procedural deviations in the Comment column immediately.

4. Data Processing (Calculations Worksheet):

* Link formulas to the Raw_Data sheet to compute:

* Mean of duplicates for each QC level, within each run.

* Daily mean for each QC level across both runs.

* Range (difference) between duplicate measurements.

* Do not overwrite or modify raw data.

5. Statistical Analysis (Summary_Statistics Worksheet): * Calculate as per EP05-A3: * Repeatability (Sr): Standard deviation of all duplicate differences across the study. * Within-Run Variance: Derived from replicate data. * Between-Run/Day Variance: Derived from daily means. * Within-Laboratory Precision (SwL): The square root of the sum of within-run and between-run variance components.

Visualizing the Data Collection and Analysis Workflow

Diagram Title: EP05-A3 Data Management Workflow

Diagram Title: EP05 Data Hierarchy and Traceability Links

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for EP05-A3 Precision Studies

| Item | Example Product/Category | Function in Precision Evaluation |

|---|---|---|

| Characterized QC Materials | Third-party assayed quality controls (e.g., Bio-Rad Liquichek, Siemens) | Serve as stable, matrix-matched test samples with known ranges for calculating precision. |

| Calibrators with Traceable Lot | Manufacturer-provided calibration standards. | Ensures analytical traceability; lot number is critical metadata for investigating shift. |

| Matrix-Matched Sample Diluent | Human serum albumin, charcoal-stripped serum. | For preparing dilution linearity studies and ensuring consistent sample background. |

| Automated Liquid Handler | Hamilton Microlab STAR, Tecan Fluent. | To minimize manual pipetting variability, a key source of within-run imprecision. |

| Laboratory Information Management System (LIMS) | LabWare, LabVantage, SampleManager. | For full audit trail, electronic data capture, and enforcing data integrity rules beyond spreadsheets. |

| Statistical Software Package | JMP, Minitab, R (with nlme or VCA package), SAS. |

For rigorous calculation of variance components as per EP05-A3 statistical model. |

| Version-Controlled Cloud Storage | SharePoint, LabArchives ELN, Box. | To maintain a single, accessible master file with version history for the data collection spreadsheet. |

Advanced Practices for Enhanced Traceability

- Cell Validation: Use data validation lists (e.g., for

Sample_Type,Analyst) to prevent entry errors. - Protected Sheets/Locked Cells: Lock all cells except those designated for data entry to prevent accidental formula corruption.

- Named Ranges: Use named ranges for key data blocks to make formulas in the

Calculationssheet more readable and less prone to reference errors. - Dynamic Timestamps: Use worksheet functions (e.g.,

NOW()) to automatically record the time of data entry, though manual verification is still required. - Digital Sign-Off: Incorporate a final row or sheet where the analyst and reviewing scientist provide electronic signatures (typed names and dates) to confirm data review.

Adherence to these spreadsheet organization practices creates a robust, transparent, and statistically sound foundation for precision estimation, directly supporting the data integrity requirements of CLSI EP05-A3 and the broader objectives of rigorous scientific research in drug development.

This technical guide, framed within a broader thesis on the Clinical and Laboratory Standards Institute (CLSI) EP05-A3 evaluation guidelines, provides a detailed protocol for quantifying the components of measurement precision in quantitative assay validation. Precision, defined as the closeness of agreement between independent test results, is decomposed into within-run, between-run, and between-day variances to identify sources of variability in analytical systems.

The CLSI EP05-A3 guideline, "Evaluation of Precision of Quantitative Measurement Procedures," is the definitive standard for precision studies in clinical laboratory medicine and bioanalysis. It provides a rigorous experimental design and statistical methodology for estimating various variance components. The core principle involves a nested (hierarchical) experimental design where repeated measurements are made within runs, runs are repeated within days, and days are repeated over a defined period. The total variance (σ²total) is the sum of these independent variance components: σ²total = σ²within-run + σ²between-run + σ²_between-day.

Experimental Protocol

Study Design

A minimum of 20 days is recommended by EP05-A3. The classic design involves:

- Two concentration levels: Typically, a low (near medical decision point) and a high concentration of analyte.

- Duplicate measurements per run: Two aliquots of each concentration level are tested in one run.

- Two runs per day: The above duplicate testing is performed in two separate runs within a single day.

- Daily repetition: This entire process is repeated for 20 separate days.

This generates 80 data points per concentration level (2 aliquots/run × 2 runs/day × 20 days = 80).

Materials and Reagent Solutions (The Scientist's Toolkit)

| Item | Function in Precision Studies |

|---|---|

| Stable, Matrix-Matched QC Materials or Patient Pools | Serves as the test sample. Must be stable, homogenous, and mimic the patient sample matrix to provide realistic precision estimates. |

| Calibrators | Used to establish the assay's calibration curve. Consistent calibration is critical for separating analytical variance from calibration drift. |

| Primary Reagent Kit | The core chemistry or immunoassay components. Lot-to-lot consistency of reagents is a potential source of between-day variance. |

| Analyzer/Instrumentation | The measurement platform. Instrument performance, maintenance, and environmental conditions contribute to all variance components. |

| Data Collection Software (LIMS/ELN) | Essential for accurate, structured recording of all raw data, run identifiers, timestamps, and operator information. |

Detailed Step-by-Step Procedure

- Preparation: Aliquot the QC materials for the two concentration levels. Ensure all reagents, calibrators, and instruments are prepared per manufacturer instructions.

- Daily Calibration: Perform a full calibration of the instrument at the beginning of each day of testing, as per the laboratory's standard protocol.

- Run 1: In the morning, analyze the two aliquots (A1, A2) of the low-concentration sample and the two aliquots (B1, B2) of the high-concentration sample in a single, continuous run. Record all results with a unique run ID.

- Run 2: After a minimum interval of 2 hours (or as practically feasible), repeat Step 3 using new aliquots from the same sample pools. Use the same calibration curve. This constitutes the second run of the day.

- Daily Repetition: Repeat Steps 2-4 for a total of 20 non-consecutive days, simulating typical laboratory operational conditions.

- Data Tabulation: Organize data hierarchically: Day > Run > Replicate.

Statistical Analysis & Calculation of Variance Components

The data are analyzed using a nested Analysis of Variance (ANOVA) model.

Data Structure & Calculations

For each concentration level separately, calculate the following sums of squares (SS) and mean squares (MS):

- Mean of All Data (Grand Mean): (\bar{X})

- Mean for each Day (i): (\bar{X}_i)

- Mean for each Run (j) within Day (i): (\bar{X}_{ij})

| Source of Variation | Degrees of Freedom (df) | Sum of Squares (SS) | Mean Square (MS) | Expected Mean Square (EMS) |

|---|---|---|---|---|

| Between Days | (d-1) | (SS{day} = 2 * 2 * \sum{i=1}^{d} (\bar{X}_i - \bar{X})^2) | (MS{day} = SS{day} / (d-1)) | (σ^2w + 2σ^2r + 4σ^2_d) |

| Between Runs (Within Day) | (d*(2-1)) | (SS{run} = 2 * \sum{i=1}^{d} \sum{j=1}^{2} (\bar{X}{ij} - \bar{X}_i)^2) | (MS{run} = SS{run} / (d)) | (σ^2w + 2σ^2r) |

| Within Run | (d2(2-1)) | (SS{within} = \sum{i=1}^{d} \sum{j=1}^{2} \sum{k=1}^{2} (X{ijk} - \bar{X}{ij})^2) | (MS{within} = SS{within} / (2d)) | (σ^2_w) |

Where:

- (d) = number of days (20)

- (σ^2_w) = Within-run variance

- (σ^2_r) = Between-run variance

- (σ^2_d) = Between-day variance

Variance Component Estimation

Solve the EMS equations to isolate each variance component:

- Within-Run Variance: (σ^2w = MS{within})

- Between-Run Variance: (σ^2r = (MS{run} - MS_{within}) / 2)

- Between-Day Variance: (σ^2d = (MS{day} - MS_{run}) / 4)

Precision is typically expressed as standard deviation (SD) and coefficient of variation (CV%).

| Variance Component | Variance (σ²) | Standard Deviation (SD) | Coefficient of Variation (CV%) |

|---|---|---|---|

| Within-Run | (σ^2_w) | (SDw = \sqrt{σ^2w}) | (CVw = (SDw / \bar{X}) * 100\%) |

| Between-Run | (σ^2_r) | (SDr = \sqrt{σ^2r}) | (CVr = (SDr / \bar{X}) * 100\%) |

| Between-Day | (σ^2_d) | (SDd = \sqrt{σ^2d}) | (CVd = (SDd / \bar{X}) * 100\%) |

| Total | (σ^2{total} = σ^2w + σ^2r + σ^2d) | (SD{total} = \sqrt{σ^2{total}}) | (CV{total} = (SD{total} / \bar{X}) * 100\%) |

Note: If any variance component estimate is negative, it is set to zero, as variance cannot be negative. This indicates that component is negligible.

Example Data Table (Hypothetical High Concentration)

The following table presents summary data from a hypothetical 20-day precision study for a high-concentration sample with a grand mean of 100.0 units.

| Statistical Component | Calculated Value | Standard Deviation (SD) | CV% |

|---|---|---|---|

| Within-Run (MS~within~) | 1.44 | 1.20 | 1.20% |

| Between-Run (MS~run~) | 2.89 | - | - |

| Between-Day (MS~day~) | 6.76 | - | - |

| Estimated σ²~w~ | 1.44 | 1.20 | 1.20% |

| Estimated σ²~r~ | 0.73 | 0.85 | 0.85% |

| Estimated σ²~d~ | 0.97 | 0.98 | 0.98% |

| Total Precision | 3.14 | 1.77 | 1.77% |

Visualizing the Nested Design and Data Flow

Nested Precision Study Workflow

Decomposition of Total Variance into Components

Within the context of clinical laboratory standardization, the CLSI EP05-A3 guideline provides the foundational framework for evaluating the precision of quantitative measurement methods. This document serves as an in-depth technical guide for researchers and drug development professionals, focusing on the critical final step: interpreting precision estimates against established performance goals, such as Total Allowable Error (TEa). The move from raw statistical output to a definitive acceptability judgment is a pivotal decision point in method validation and verification.

Performance Goals and Acceptability Criteria

The interpretation of precision studies is not performed in a vacuum. It requires comparison to objective criteria, which are often derived from biological variation, regulatory standards (e.g., FDA, EMA), or clinically defined limits. Total Allowable Error (TEa) represents the maximum error (systematic + random) that can be tolerated without adversely affecting clinical decision-making.

For precision alone, a common criterion is that the method's total imprecision (expressed as %CV) should be less than or equal to one-half of the TEa. This conservative approach reserves the remaining error budget for potential bias.

Table 1: Common Sources of Performance Goals (TEa)

| Source | Basis | Example Application |

|---|---|---|

| Biological Variation | Based on within-subject (CVI) and between-subject (CVG) variation. Desirable performance: CV < 0.5*CVI. | Endocrinology, therapeutic drug monitoring. |

| Clinical Guidelines | Defined by professional societies (e.g., ADA, NACB) based on outcome studies. | Hemoglobin A1c, cardiac troponin. |

| Regulatory Models | Fixed limits or percentages provided by agencies (e.g., CLIA '88). | Common chemistry analytes (e.g., Na+, K+, glucose). |

| State of the Art | Based on the performance achievable by peer laboratories or instruments. | Novel biomarkers without established criteria. |

Core Experimental Protocol: EP05-A3 Precision Evaluation

The following methodology is derived from CLSI EP05-A3.

1. Experimental Design:

- Perform a nested (hierarchical) experiment spanning ≥ 20 days.

- Analyze two replicates per run of at least two concentration levels (normal and abnormal) of a stable material.

- A single run is performed per day, with separate preparations for each replicate.

2. Statistical Analysis:

- Calculate variance components and standard deviations using analysis of variance (ANOVA):

- sr: Repeatability (within-run) standard deviation.

- swr: Within-laboratory (total) standard deviation, incorporating both within-run and between-day variations.

- Convert to coefficients of variation: CVr and CVwr.

Table 2: Example Precision Study Output and Assessment

| Component | Estimate (Units) | %CV | Performance Goal (½ TEa = 3.0%) | Acceptable? |

|---|---|---|---|---|

| Level 1 (Normal) | ||||

| Repeatability (sr) | 0.8 mg/dL | 2.1% | ≤ 3.0% | Yes |

| Total Precision (swr) | 1.1 mg/dL | 2.9% | ≤ 3.0% | Yes |

| Level 2 (Abnormal) | ||||

| Repeatability (sr) | 1.5 mg/dL | 3.5% | ≤ 3.0% | No |

| Total Precision (swr) | 2.2 mg/dL | 5.1% | ≤ 3.0% | No |

Interpretation and Decision Logic

The final assessment involves comparing the calculated confidence intervals for each precision component against the defined goal. EP05-A3 emphasizes using the upper confidence limit (UCL) for standard deviation or CV for comparison.

Diagram 1: Acceptability Decision Logic Flow

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Precision Studies

| Item | Function in EP05-A3 Studies |

|---|---|

| Commutable, Matrix-Matched QC or Serum Pools | Stable, homogeneous materials that mimic patient samples, essential for realistic precision estimation across multiple days. |

| Certified Reference Materials (CRMs) | Materials with assigned values traceable to a higher-order standard, used to validate accuracy in conjunction with precision. |

| Liquid-stable, Multi-level Assayed Controls | Commercial controls with established ranges for verifying instrument performance throughout the long-term study. |

| Calibrators Traceable to Reference Methods | Ensures the measurement scale is consistent, separating precision from potential calibration bias. |

| Data Collection & Statistical Software (e.g., R, SAS, dedicated IVD software) | Essential for performing nested ANOVA and calculating variance components with confidence intervals as per EP05-A3. |

Advanced Considerations: Integrating with Other CLSI Guidelines

Precision assessment does not stand alone. The final interpretation often requires integration with studies of bias (EP09-A3, EP15-A3) to estimate total error (TE = |Bias| + 1.65 * CVwr), which is then compared directly to the TEa.

Diagram 2: Integration of Precision and Bias for Total Error Assessment

Interpreting the output of an EP05-A3 precision study through the lens of clinically or biologically derived performance goals transforms statistical results into a definitive, risk-based judgment on method acceptability. A rigorous, well-executed protocol combined with appropriate performance criteria forms the cornerstone of reliable method validation, ensuring that laboratory measurements are fit for their intended purpose in patient care and drug development.

Solving Common EP05-A3 Challenges and Optimizing Study Outcomes

1. Introduction within the CLSI EP05-A3 Framework The Clinical and Laboratory Standards Institute (CLSI) EP05-A3 guideline provides a standardized protocol for evaluating the precision of quantitative measurement procedures. Within a broader research thesis on these guidelines, a critical challenge is the systematic investigation of precision studies that fail to meet acceptable performance criteria. This whitepaper provides an in-depth technical guide for diagnosing and resolving sources of excessive variance, moving beyond simple compliance to root-cause analysis.

2. Hierarchical Variance Decomposition: The Core Model The EP05-A3 experimental design isolates variance components through a nested ANOVA model. Excessive total variance can stem from one or more levels of this hierarchy.

Table 1: Primary Variance Components and Diagnostic Triggers

| Variance Component | EP05-A3 Term | Typical Source | Diagnostic Trigger (Excessive %) |

|---|---|---|---|

| Between-Run | Day-to-Day | Calibrator lot changes, environmental shifts, major reagent lot changes | > 50% of total variance |

| Between-Day | Within-Run | Instrument performance drift, operator change, daily preparation | Significant if Between-Run is low but total is high |

| Within-Run | Repeatability | Pipetting variability, short-term instrument noise, sample heterogeneity | > 70% of total variance suggests a fundamental assay instability |

| Between-Operator | -- (Special Study) | Technique differences in manual steps | Revealed by an operator*day interaction term in ANOVA |

3. Experimental Protocols for Targeted Investigation

Protocol A: Reagent & Calibrator Inter-Day Variance Test

- Objective: Isolate variance due to reagent lot/channel or calibrator instability.

- Methodology: Using a single QC level, perform 2 replicates per run, 2 runs per day, for 5 days. However, introduce a deliberate change: use Reagent Lot A for days 1-3 and Reagent Lot B for days 4-5. All other factors (instrument, operator, calibrator lot) are held constant.

- Analysis: Perform nested ANOVA. A significant increase in Between-Run variance localized to the lot change day pinpoints the reagent as the source.

Protocol B: Operator-Dependent Variance Protocol

- Objective: Quantify the contribution of individual analyst technique.

- Methodology: Employ two operators (Op1, Op2). Design: 1 run per day, 2 replicates per run, for 10 days. Operators alternate days but analyze the same QC sample. Ensure each operator uses independently prepared aliquots/reagents to capture full procedural variance.

- Analysis: Two-way ANOVA with factors "Operator" and "Day". A significant "Operator" effect or "Operator*Day" interaction indicates technique-driven variance.

Protocol C: Instrument-Specific Noise Assessment

- Objective: Diagnose within-run (repeatability) variance from instrument subsystems.

- Methodology: On a single instrument, run a high-value and low-value QC sample 20 times sequentially in one run. Analyze the data for trends (e.g., photometer decay) vs. random scatter.

- Analysis: Calculate moving averages and control limits. Systematic drift suggests dispenser, incubator, or detector issues. Pure random scatter suggests pipetting or mixing variability.

4. Diagnostic Pathways and Workflows

Diagram Title: Diagnostic Decision Tree for Excessive Variance Components

Diagram Title: 7-Step Troubleshooting Workflow for Precision Studies

5. The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Precision Investigation

| Item | Function in Troubleshooting | Example/Note |

|---|---|---|

| Commutable, Stable QC Material | Serves as a constant analyte source across experiments; must mimic patient sample matrix. | Liquid, serum-based, multi-analyte controls with long-term stability. |

| Calibrators from Multiple Lots | Isolates calibrator-specific variance from reagent or instrument variance. | Use 3 distinct lots for a robust special study. |

| Reagent Lots with Intentionally Wide Expiry Windows | Tests the impact of reagent aging and lot-to-lot variability. | Procure lots expiring in 1, 6, and 12 months. |