High-Throughput Virology: Revolutionizing Viral Vector Production for Next-Generation Therapies

This article explores the transformative impact of high-throughput virology (HTV) platforms on viral vector manufacturing for gene therapies and vaccines.

High-Throughput Virology: Revolutionizing Viral Vector Production for Next-Generation Therapies

Abstract

This article explores the transformative impact of high-throughput virology (HTV) platforms on viral vector manufacturing for gene therapies and vaccines. Aimed at researchers, scientists, and drug development professionals, it provides a comprehensive analysis spanning foundational principles, cutting-edge methodological applications, advanced troubleshooting for yield and quality optimization, and rigorous validation strategies. The content synthesizes current technological advancements, including the integration of robotic automation, Design of Experiments (DoE), and machine learning, to address critical industry challenges such as overcoming innate antiviral defenses and standardizing scalable bioprocesses. By offering a detailed roadmap from discovery to commercial production, this resource equips professionals with the knowledge to accelerate the development of effective viral vector-based biologics.

The High-Throughput Virology Revolution: Core Principles and Industry Impact

Defining High-Throughput Virology (HTV) in Modern Biomanufacturing

High-Throughput Virology (HTV) represents a transformative approach in modern biomanufacturing and antiviral drug discovery, leveraging automation, miniaturization, and advanced data analytics to rapidly process thousands of viral samples or compounds. This paradigm addresses critical bottlenecks in virology research, from accelerating the development of viral vector-based gene therapies to identifying novel antiviral compounds. This application note delineates the core principles, methodologies, and applications of HTV, providing detailed protocols for screening antiviral compounds against the Chikungunya virus and for high-throughput viral titer determination. Supported by quantitative data and standardized workflows, this document serves as a foundational resource for researchers and scientists engaged in advancing virology and biomanufacturing.

High-Throughput Virology (HTV) is an interdisciplinary framework that applies high-throughput screening (HTS) technologies to virological research and biomanufacturing. Its primary objective is to expedite the systematic analysis of viral behaviors, virus-host interactions, and antiviral agents at an unprecedented scale and speed. The global viral vector manufacturing market, a key beneficiary of HTV methodologies, is projected to grow from US$1.74 billion in 2024 to US$5.76 billion by 2031, reflecting a compound annual growth rate (CAGR) of 18.8% [1]. This growth is propelled by the rising pipeline of gene and cell therapies, increased investment in biomanufacturing infrastructure, and technological innovations in single-use bioreactors and closed-system processing [1]. HTV is critical for supporting this expansion, enabling the rapid, reproducible, and cost-effective development of viral vectors for therapeutic and vaccine applications.

Core HTV Applications in Biomanufacturing and Antiviral Discovery

HTV methodologies are instrumental across multiple domains, two of which are highlighted below with quantitative outcomes.

Antiviral Compound Screening

The discovery of antiviral drugs necessitates screening vast chemical libraries to identify compounds that inhibit viral replication. A recent study established a quantitative high-throughput screening (qHTS) pipeline to identify inhibitors of the Chikungunya virus (CHIKV) nsP2 protease, a critical viral replication enzyme [2]. The research utilized a fluorescence resonance energy transfer (FRET)-based assay in a 1,536-well format to screen approximately 31,000 unique small molecules from drug repurposing and medicinal chemistry libraries [2]. This approach generated concentration–response curves directly from the primary screen, thereby reducing false-positive and false-negative rates common in conventional screening [2].

Table 1: Key Assay Parameters for CHIKV nsP2 Protease Screening

| Assay Component | Description | Performance/Value |

|---|---|---|

| Enzyme | Recombinant CHIKV nsP2 protease domain (nsP2pro) | Catalytic efficiency (kcat/Km) for nsp3/4 site peptide: ~14,500 M⁻¹s⁻¹ [2] |

| Substrate | 15-amino acid fluorogenic peptide (nsp3/4 cleavage site, DELRLDRAGG/YIFSS) | Signal-to-Background (S/B) ratio: >3-fold with 150 nM enzyme [2] |

| Throughput | 1,536-well plate format | ~31,000 compounds screened [2] |

| Hit Validation | Counter-screening with full-length nsP2, selectivity assays, and a cell-based split nanoluciferase reporter | Identified novel, cell-active nsP2 inhibitor compounds [2] |

High-Throughput Viral Titer Determination

Accurate viral titration is fundamental in biomanufacturing for quality control and potency assessment. Conventional methods like plaque assays (PFU) and 50% tissue culture infectious dose (TCID₅₀) are time-consuming (taking 5-12 days) and labor-intensive [3]. A high-throughput colorimetric viral titer assay was developed using a tetrazolium-based MTS reagent, which is reduced to a colored formazan product by metabolically active cells [3]. The absorbance of formazan at 490 nm is inversely proportional to the viral load causing cell death. This method demonstrated a linear range for rapid titration between 100 and 2,000 TCID₅₀/ml for porcine respiratory coronavirus and 500 and 10⁶ PFU/ml for bovine alpha herpesvirus 1 [3].

Table 2: Comparison of Viral Titration Methods

| Parameter | Traditional TCID₅₀/PFU | High-Throughput MTS Assay |

|---|---|---|

| Throughput | Low (laborious serial dilutions) | High (96-well plate format, no dilutions within linear range) [3] |

| Time to Result | 5-12 days [3] | Rapid (protocol can be completed within days) [3] |

| Data Output | Discrete, quantal (infected/not infected) [3] | Continuous, quantitative (cell viability percentage) [3] |

| Subjectivity | High (relies on expert observation) [3] | Low (objective colorimetric readout) [3] |

| Primary Application | Gold standard, low-throughput quantification | Rapid screening for drug development and viral survival studies [3] |

Detailed Experimental Protocols

Protocol 1: qHTS for CHIKV nsP2 Protease Inhibitors

Objective: To identify small molecule inhibitors of CHIKV nsP2 protease activity using a FRET-based qHTS approach [2].

Materials:

- Recombinant Protein: Purified CHIKV nsP2 protease domain (nsP2pro) or full-length nsP2 (see Reagent Solutions).

- Substrate: A 15-amino acid peptide encompassing the natural nsp3/4 cleavage site (DELRLDRAGG/YIFSS), labeled with a 5-TAMRA fluorophore and QSY7 quencher.

- Compounds: Library of small molecules dissolved in DMSO.

- Equipment: 1,536-well microplates, a multi-mode plate reader capable of detecting fluorescence (excitation/emission appropriate for TAMRA), and liquid handling automation.

Procedure:

- Assay Setup: In a 1,536-well plate, dispense 2 µL of assay buffer into all wells.

- Compound Addition: Pin-transfer 10 nL of each compound from the library or DMSO control into respective wells.

- Enzyme Addition: Add 2 µL of nsP2pro enzyme solution (150 nM final concentration) to all wells using a dispenser. Centrifuge the plate briefly to mix.

- Reaction Initiation: Add 2 µL of the fluorogenic peptide substrate (5 µM final concentration) to start the reaction.

- Incubation and Reading: Incubate the plate at room temperature for a predetermined period (e.g., 60-90 minutes). Measure the fluorescence intensity at appropriate wavelengths.

- Data Analysis: Calculate the percentage inhibition for each compound using positive (no enzyme) and negative (DMSO only) controls. Fit concentration-response curves to determine IC₅₀ values for active compounds.

Protocol 2: High-Throughput Viral Titer Assay Using MTS

Objective: To rapidly determine the infectious titer of a viral sample by measuring virus-induced cytopathic effects (CPE) via a colorimetric readout [3].

Materials:

- Cells: Permissive cell line (e.g., Vero cells for CHIKV).

- Reagent: MTS tetrazolium compound, often commercially available as a pre-formulated solution (e.g., CellTiter 96 AQueous One Solution).

- Consumables: 96-well clear flat-bottom tissue culture-treated plates.

- Equipment: Plate reader capable of measuring absorbance at 490 nm.

Procedure:

- Cell Seeding: Seed a suspension of permissive cells at a standardized density (e.g., 1x10⁴ cells/well) in a 96-well plate. Incubate for 24 hours at 37°C, 5% CO₂ to form a confluent monolayer.

- Viral Infection: Prepare serial dilutions of the viral sample in culture medium. Remove the medium from the cell plate and inoculate triplicate wells with 100 µL of each viral dilution. Include mock-infected wells (medium only) as a negative control and a virus-induced cytotoxicity control (e.g., cells treated with a lysing agent) as a positive control.

- Incubation: Incubate the plate for 24-72 hours (duration depends on the virus kinetics) until CPE is evident in the positive control wells.

- Viability Staining: Carefully remove the supernatant from all wells. Add a homogeneous mix of 100 µL fresh culture medium and 20 µL MTS reagent to each well.

- Formazan Development: Incubate the plate for 1-4 hours at 37°C, protected from light.

- Absorbance Measurement: Measure the absorbance at 490 nm using a plate reader.

- Data Analysis:

- Calculate cell viability for each well using the formula:

Cell Viability (%) = [(Atested - AMTS) / (ACTRL100% - AMTS)] * 100whereAtestedis the absorbance of the test well,AMTSis the background absorbance of the MTS-medium solution, andACTRL100%is the average absorbance of mock-infected cells [3]. - Plot cell viability against the log viral dilution or known standard titers to determine the unknown sample's titer.

- Calculate cell viability for each well using the formula:

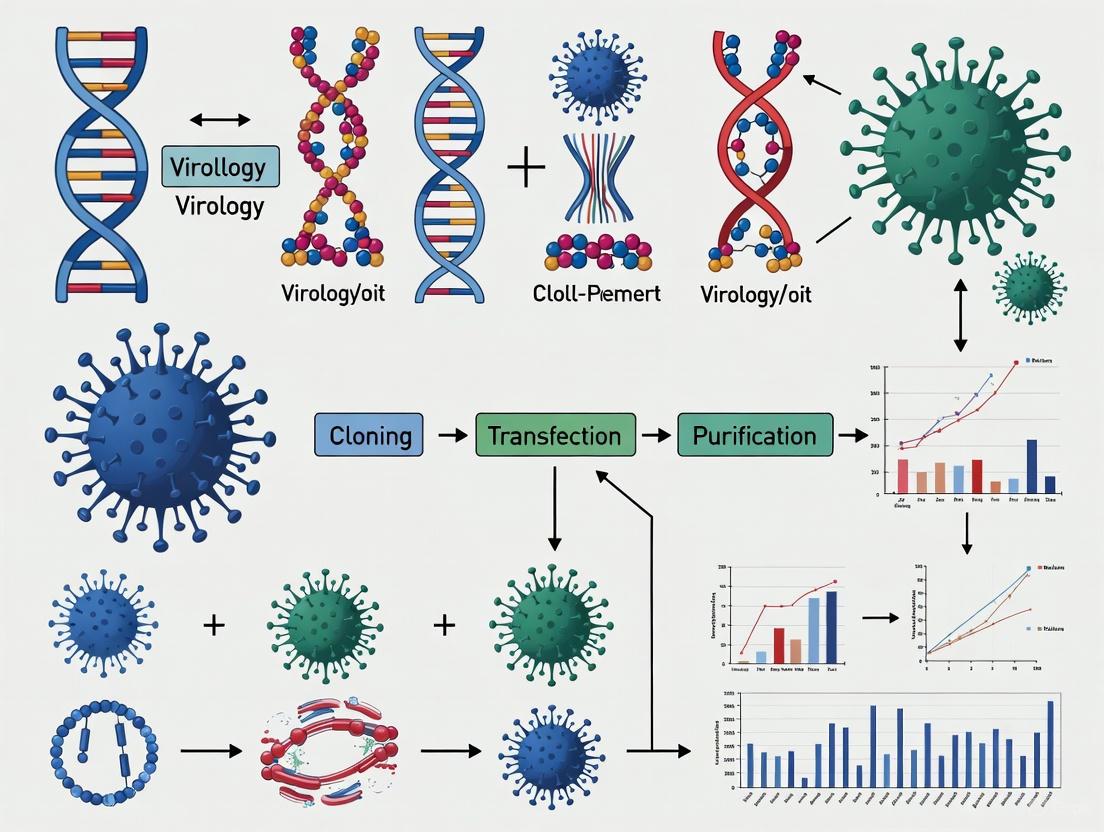

Workflow Visualization

Diagram 1: Generic High-Throughput Virology Screening Workflow.

Diagram 2: Antiviral Screening Cascade for CHIKV Inhibitors [2].

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Reagents for High-Throughput Virology Applications

| Reagent / Material | Function / Application | Example / Specification |

|---|---|---|

| Recombinant Viral Enzymes | Target for biochemical HTS; e.g., CHIKV nsP2 protease for antiviral discovery [2]. | Purified C-terminal 329 aa protease domain (nsP2pro) or full-length protein [2]. |

| Fluorogenic Peptide Substrates | Report on enzymatic activity in real-time via fluorescence increase upon cleavage. | 15-amino acid peptide with nsp3/4 cleavage site, 5-TAMRA/QSY7 FRET pair [2]. |

| MTS Tetrazolium Reagent | Colorimetric measurement of cell metabolic activity for viral CPE quantification and titer determination [3]. | Commercial solution (e.g., CellTiter 96 AQueous One); absorbance read at 490 nm [3]. |

| Specialized Cell Lines | Permissive cells for viral propagation, infection studies, and cell-based antiviral assays. | Swine testicular (ST) cells, Madin-Darby bovine kidney (MDBK) cells, Vero cells [3] [4]. |

| Automated Image Analysis Software | High-throughput, accurate quantification of infected cells in antiviral screens. | MvTec Halcon software for automated detection of infected/uninfected cells (Pearson correlation: 0.9886 vs. manual count) [4]. |

The Critical Need for HTV in Gene Therapy and Vaccine Development

The fields of gene therapy and vaccinology are undergoing a transformative shift, driven by the escalating demands for rapid development and large-scale manufacturing of biologic products. High-Throughput Virology (HTV) has emerged as a critical discipline, enabling the acceleration of research, enhancement of safety profiles, and scaling of production processes that are essential for modern biologics. The successful global response to the COVID-19 pandemic underscored the indispensable role of HTV, where platform technologies like viral vectors and mRNA formulations allowed for unprecedented speed in vaccine development and deployment [5]. This article details specific, high-throughput applications and protocols that are foundational to advancing gene therapy and next-generation vaccine technologies, providing a practical guide for researchers and drug development professionals.

HTV Applications in Vector Engineering and Development

CRISPR-Cas for High-Throughput Viral Genome Engineering

The CRISPR-Cas system has revolutionized viral genome editing, offering a powerful, simple, and efficient alternative to traditional homologous recombination or bacterial artificial chromosome (BAC) systems, which can be time-consuming and laborious, especially for viruses with large genomes [6].

Functional Principle: The system consists of a Cas nuclease and a single-guide RNA (sgRNA). The chimeric sgRNA directs Cas9 to bind to a target DNA fragment adjacent to a Protospacer Adjacent Motif (PAM), stimulating a double-stranded break (DSB). The cellular repair of this DSB via non-homologous end joining (NHEJ) or homology-directed repair (HDR) enables precise gene knockouts, insertions, or deletions [6].

High-Throughput Application: CRISPR-Cas is not only a tool for targeted gene editing but also facilitates high-throughput functional genomics. Genome-wide CRISPR knockout (CRISPR KO) or CRISPR interference (CRISPRi) screens can identify host factors critical for viral infection. For instance, such screens have identified essential receptors for SARS-CoV-2 and noroviruses, as well as host factors involved in the life cycles of viruses like influenza and Dengue virus [7].

Table 1: CRISPR-Cas Systems in High-Throughput Virology

| CRISPR System | Target | Primary Use in Virology | Key Advantage |

|---|---|---|---|

| Cas9 | DNA | Viral genome editing, identification of DNA virus host factors [6] [7] | Precise DNA cleavage, versatile for knockout screens |

| Cas12a | DNA | Viral genome editing, diagnostics [7] | Targets T-rich PAM sites, multiplexing capability |

| Cas13 | RNA | Targeting RNA viruses, viral RNA detection [7] | RNA cleavage, minimizes genomic integration risk |

| dCas9 (CRISPRi/a) | DNA | Transcriptional regulation of viral or host genes [7] | Silencing or activating genes without altering DNA |

High-Throughput Analytical Methods for Vector Characterization

As recombinant Adeno-Associated Virus (rAAV) has become a leading gene therapy vector, the need for high-throughput analytics to determine product potency and safety has intensified. The viral genome (Vg) titer, a standard potency measure, does not distinguish between intact genomes and truncated, non-functional species [8].

Novel Hybrid Capture-MSD Method: A high-throughput RNA-DNA hybrid capture-multiplex meso scale discovery (MSD) method has been developed to quantify the integrity of the rAAV genome. This method specifically quantifies intact versus truncated genomes for both the plus and minus strands individually, providing data that correlates strongly with rAAV activity [8]. This represents a significant advance over conventional titering, enabling more reliable dosing in preclinical and clinical studies.

HTV in Adventitious Agent Safety Testing

Ensuring the absence of adventitious viruses is a critical safety requirement for biological products. High-Throughput Sequencing (HTS), also known as next-generation sequencing (NGS), is now recognized as a powerful alternative to conventional in vivo and in vitro assays for broad virus detection [9].

Validated HTS Workflow: A multi-laboratory study demonstrated the application of short-read HTS for detecting a panel of five viruses (EBV, FeLV, RSV, Reo1, PCV1) spiked into a high-titer adenovirus background. The study evaluated the sensitivity and breadth of detection using independent protocols for sample processing, sequencing, and bioinformatics analysis [9].

Key Findings:

- All participating laboratories detected all five spiked viruses at a concentration of 10^4 genome copies per mL (GC/mL) using both targeted and non-targeted bioinformatic analyses.

- Most laboratories detected all viruses at 10^3 GC/mL with targeted analysis, demonstrating high sensitivity.

- The study highlighted that optimization of steps in the HTS workflow can significantly improve the limit of detection [9].

Table 2: HTS Detection Sensitivity for Adventitious Viruses

| Virus Spike Level (GC/mL) | Targeted Analysis Detection | Non-Targeted Analysis Detection | Key Observations |

|---|---|---|---|

| 10^4 | 5/5 viruses by all labs [9] | 5/5 viruses by all labs [9] | Robust detection at this level by all methodologies |

| 10^3 | 5/5 viruses by 5/5 labs [9] | Variable (e.g., all 5 viruses or only 2) [9] | Targeted analysis provides more consistent sensitivity |

| 10^2 | Variable (e.g., 3/5 viruses) [9] | Variable [9] | Detection at this level is protocol-dependent |

HTV in Antiviral Screening and Vaccine Design

Comparative High-Throughput Screening for Entry Inhibitors

Viral entry is an ideal target for therapeutic intervention. For highly pathogenic viruses, pseudotyped virions enable safe, high-throughput screening (HTS) in BSL-2 facilities [10].

Protocol: Comparative HTS for Entry Inhibitors

- Principle: HIV-based pseudovirions are generated by incorporating the glycoproteins (GP) of target viruses (e.g., Marburg virus, H5N1 influenza, Lassa virus). These pseudovirions encode a luciferase reporter gene, allowing infection to be quantified via luminescence [10].

- Screening Workflow:

- Production: Pseudovirions are produced by co-transfecting 293T cells with plasmids encoding the target GP and an HIV-based reporter vector.

- Assay: Target cells (e.g., A549) are seeded in 384-well plates. Compounds are mixed with pseudovirions and transferred to the cell plates.

- Readout: After 48 hours, luciferase activity is measured. Inhibition is calculated as a percentage reduction in luminescence compared to controls [10].

- Comparative Advantage: Screening a compound library against multiple pseudovirion types simultaneously allows for the immediate identification of virus-specific hits and the reduction of false positives common in HTS [10].

Accelerating Vaccine Development with CRISPR

CRISPR-Cas is a game-changer in vaccine development. It enables the rapid generation of recombinant viral vectors and attenuated live vaccines with precise genomic modifications. Furthermore, it facilitates the creation of gene-edited animal models that are resistant to key infectious diseases, a significant step for both animal health and agricultural biosecurity [7].

Application in Animal Health:

- PRRSV-Resistant Pigs: By using CRISPR-Cas to knockout the CD163 gene in pigs, researchers have successfully generated animals fully resistant to Porcine Reproductive and Respiratory Syndrome Virus (PRRSV), a major agricultural pathogen [7].

- Avian Influenza Resistance: CRISPR editing of the ANP32 gene family in chickens has created resistance to avian influenza infection [7].

These examples demonstrate how HTV approaches can directly engineer disease resistance, bridging the gap between basic research and applied therapeutic outcomes.

Essential Research Reagent Solutions

The successful implementation of HTV relies on a standardized toolkit of reagents and platforms. The following table details key materials used in the featured applications.

Table 3: Research Reagent Solutions for High-Throughput Virology

| Reagent / Solution | Function in HTV | Example Application |

|---|---|---|

| CRISPR sgRNA Libraries | Enables genome-wide loss-of-function or gain-of-function screens | Identification of host factors essential for SARS-CoV-2 replication [7] |

| Viral Pseudotyping Systems | Safe surrogate for studying entry of pathogenic viruses; core of HTS assays | Screening for entry inhibitors against Marburg, H5N1, and Lassa viruses [10] |

| CBER NGS Virus Reagents | Standardized reference panel for HTS assay validation | Evaluating sensitivity and breadth of adventitious virus detection [9] |

| High-Throughput AAV Analytics | Quantifies intact vs. truncated viral genomes; correlates with potency | RNA-DNA hybrid capture-MSD for rAAV genome integrity [8] |

| Lipid Nanoparticles (LNPs) | Versatile vector for mRNA vaccine and therapy delivery | Formulation for SARS-CoV-2 mRNA vaccines [5] |

The integration of High-Throughput Virology methodologies is no longer optional but a critical necessity for advancing gene therapies and vaccines. From the precision engineering of viral vectors with CRISPR and the rigorous safety testing enabled by HTS to the rapid screening of antivirals and design of novel vaccines, HTV provides the speed, scale, and precision required to meet modern public health and therapeutic demands. The protocols and applications detailed herein provide a framework for researchers to leverage these powerful tools, driving innovation from the laboratory bench to clinical and commercial realization.

The convergence of rare disease research and high-throughput virology is catalyzing a paradigm shift in modern medicine. Driven by substantial market growth, scientific innovation, and regulatory evolution, therapeutic developments for rare diseases are increasingly informing mainstream therapeutic applications. The global rare disease treatment market, valued at approximately $232.2 billion in 2024, is projected to reach $792.8 billion by 2037, expanding at a compound annual growth rate (CAGR) of 10.35% [11]. This growth is primarily fueled by advances in precision medicine, genomic technologies, and viral vector engineering, particularly adeno-associated virus (AAV) vectors that enable efficient gene therapy delivery. High-throughput virology methods are accelerating this transition by optimizing vector production and selection, creating powerful synergies between basic virology and clinical application. These developments are transforming rare diseases from neglected areas to pioneering fronts for innovative therapies that eventually benefit broader patient populations.

Rare diseases, collectively defined as conditions affecting small patient populations, represent a significant public health challenge despite their individual rarity. With over 6,000 identified rare diseases affecting an estimated 300-400 million people globally (approximately 3.5-5.9% of the global population), these conditions constitute a substantial medical burden [12]. Approximately 72-80% of rare diseases have a known genetic origin, with about 70% manifesting during childhood [12]. The historical neglect of these conditions, attributable to limited commercial incentives and scientific challenges, has been reversed through targeted legislation like the Orphan Drug Act of 1983, which catalyzed pharmaceutical investment by creating designated pathways and incentives for rare disease therapy development [12].

The rare disease sector has emerged as an unexpected innovation driver in pharmaceutical development, with orphan drugs now representing a significant portion of new drug approvals. In recent years, over half of all new drug approvals by the FDA have been for rare disease indications [12]. This trend reflects a fundamental shift in drug development paradigms, where the focused nature of rare disease research provides ideal conditions for testing targeted therapeutic approaches, including gene therapies, antisense oligonucleotides, and other modality-based treatments that subsequently find applications in more common conditions.

Quantitative Market Landscape and Key Drivers

Market Size and Growth Projections

Table 1: Global Rare Disease Treatment Market Projections

| Year | Market Size (USD Billion) | Growth Rate | Key Influencing Factors |

|---|---|---|---|

| 2024 | 232.2 [11] | - | Base year valuation |

| 2025 | 243.1 [11] | - | Initial growth phase |

| 2030 | 374.4 [13] | 11.6% CAGR (2025-2030) [13] | Precision medicine adoption |

| 2030 | 36.5 [14] | 10.9% CAGR (2025-2030) [14] | Alternative market assessment |

| 2037 | 792.8 [11] | 10.35% CAGR (2025-2037) [11] | Long-term expansion |

The disparate market size figures from different sources reflect varying methodological approaches to market assessment but consistently demonstrate strong growth trajectories across all projections.

Epidemiological Foundations and Diagnostic Advancements

Table 2: Rare Disease Epidemiology and Diagnostic Metrics

| Parameter | Value | Significance |

|---|---|---|

| Global Prevalence | 300-400 million people [12] | Collective disease burden demonstrates market scale |

| US Prevalence | 25-30 million Americans (∼1 in 10) [12] | Substantial addressable market in developed regions |

| Diseases with Approved Treatments | ∼5% (∼95% without specific therapy) [12] | Massive unmet need driving innovation and investment |

| Average Diagnostic Delay | ∼4.5 years (25% wait >8 years) [12] | Diagnostic challenges creating opportunity for improved methods |

| Genetic Origin | 72-80% of rare diseases [12] | Rationale for genetic approaches and precision medicine |

Advances in genomic sequencing technologies are significantly addressing diagnostic challenges. Whole-exome sequencing (WES) and whole-genome sequencing (WGS) demonstrate superior diagnostic rates compared to conventional methods, with pooled rates of 0.3 and 0.4 respectively [11]. Rapid genomic sequencing has demonstrated substantial healthcare cost savings, with studies in Australia, Hong Kong, and the U.S. showing significant reductions in hospital days and associated costs [11].

Therapeutic Pipeline and Clinical Trial Landscape

Table 3: Selected Rare Disease Therapies in Clinical Development

| Drug Name | Indication | Sponsor | Phase | Key Notes | Timeline |

|---|---|---|---|---|---|

| Venglustat | Gaucher Disease Type 3 | Sanofi Genzyme | Phase 3 | Oral substrate reduction therapy | Active (Ends 2026) [11] |

| Elivaldogene autotemcel | Metachromatic Leukodystrophy | Orchard Therapeutics | Phase 3 | Autologous gene therapy, single infusion | Active (Completion 2025) [11] |

| Roctavian | Hemophilia A | BioMarin | Phase 3 | Gene therapy for factor VIII deficiency | Active (Ends 2026) [11] |

| WVE-003 | Huntington's Disease | - | Phase Ib/IIa | Allele-selective antisense oligonucleotide | Positive 2024 results [13] |

| Afamitresgene autoleucel | Synovial Sarcoma | - | Approved (2024) | Immunotherapy for rare soft tissue cancer | FDA approved August 2024 [13] |

The rich clinical pipeline reflects increasing investment in rare disease therapeutics, with both biotechnology and large pharmaceutical companies actively developing targeted approaches. The success of recently launched products demonstrates market viability, with BridgeBio Pharma's Acoramidis earning $36.7 million in U.S. sales alone shortly after its November 2024 launch for treating transthyretin amyloid cardiomyopathy [11].

High-Throughput Virology in Vector Production

AAV Vector Development Workflow

The development of adeno-associated virus (AAV) vectors represents a cornerstone technology enabling gene therapies for rare diseases. AAV has become a pivotal tool in gene therapy, providing a safe and efficient platform for long-term transgene expression [15]. The historical development of AAV, from its initial identification as a contaminant to its current clinical applications, demonstrates how virology fundamentals have been harnessed for therapeutic purposes.

Protocol: High-Throughput AAV Library Screening for Vector Optimization

Objective: To identify AAV variants with enhanced tropism, reduced immunogenicity, and improved transduction efficiency for rare disease gene therapy applications.

Materials:

- AAV Library Diversity: Combinatorial capsid libraries (>10^6 variants)

- Cell Culture Models: Primary human cells, organoids, or tissue-specific lines

- Animal Models: Humanized mouse models or non-human primates

- Sequencing Platform: Next-generation sequencing (NGS) system

- qPCR/DDPCR: For vector genome quantification

Procedure:

Library Administration

- Administer pooled AAV library to human decedents or relevant animal models

- Allow 24-72 hours for biodistribution and cellular entry

- Collect target tissues and isolate vector DNA

Recovery and Amplification

- Extract total DNA from target tissues using silica-membrane columns

- Amplify capsid coding regions with barcoded primers

- Prepare sequencing libraries with unique molecular identifiers

High-Throughput Analysis

- Sequence amplified regions using Illumina platform (minimum 50M reads)

- Map sequences to reference AAV genome

- Quantify variant abundance across tissues

Bioinformatic Selection

- Identify enriched variants with >10-fold increase in target tissues

- Exclude variants with promiscuous tropism or liver enrichment

- Select 5-10 lead candidates for secondary validation

Validation Studies

- Package candidate vectors with reporter genes

- Assess transduction efficiency in primary human cells

- Evaluate immunogenicity profile in human PBMC assays

Timeline: 8-12 weeks for primary screen, 12-16 weeks for validation

Technical Notes: Critical parameters include library diversity, administration route, and selection of clinically relevant models. The administration of AAV libraries to human decedents represents a transformative approach in AAV evolution and selection for human applications [15].

Precision Medicine and Therapeutic Modalities

Therapeutic Platform Applications

The convergence of rare disease research and precision medicine has generated multiple targeted therapeutic platforms with broad applicability:

4.1.1 Gene Therapy and Editing

- AAV-Based Gene Replacement: Successfully applied to spinal muscular atrophy (SMA) with onasemnogene abeparvovec, transforming a lethal childhood condition into a manageable disease [13]

- CRISPR-Cas9 Genome Editing: Demonstrated in Huntington's Disease models to reduce CAG repeats, with applications extending to leukodystrophies and other repeat expansion disorders [13]

- Gene Silencing: Allele-selective antisense oligonucleotides (e.g., WVE-003 for Huntington's) achieving mutant huntingtin protein reduction in clinical trials [13]

4.1.2 Enzyme Replacement and Modulation

- Enzyme Replacement Therapy (ERT): Intravenous administration of recombinant enzymes for lysosomal storage diseases including Fabry disease, Gaucher disease, and Batten disease [13]

- CFTR Modulators: Dramatic improvement in lung function and life expectancy for cystic fibrosis patients, potentially extending median survival toward normal ranges [12]

Protocol: High-Throughput Viral Vector Titer Quantification

Objective: To accurately quantify viral genome particles, physical particles, and infectious units for quality control in vector production.

Materials:

- Purified Viral Preparation: AAV, lentivirus, or other viral vectors

- qPCR/DDPCR System: With SYBR Green or probe-based chemistry

- Electron Microscope: With negative staining capability

- Cell Culture: Permissive cell lines (e.g., HEK293, Vero)

- Antibodies: Primary against viral antigens and fluorescent secondaries

Procedure:

Genome Quantification (qPCR)

- Digest vector preparation with DNase I (1 hour, 37°C) to remove unencapsidated DNA

- Inactivate DNase with EDTA (5mM final concentration, 10 minutes, 65°C)

- Proteinase K treatment to release viral genomes (1 hour, 56°C)

- Extract DNA using silica-membrane columns

- Perform qPCR with standards of known concentration

- Calculate vector genomes/mL using standard curve

Physical Particle Count (Electron Microscopy)

- Fix virus preparation with 2.5% glutaraldehyde (1:1 ratio, ≥1 hour)

- Pellet particles on carbon/Formvar-coated copper grids (10 minutes, 12,000 × g)

- Stain with 2% tungstophosphoric acid (pH 6.0)

- Count particles in 10 grid squares (1 particle/square = 1.5 × 10^5 particles/mL)

- Calculate particles/mL based on counted average

Infectious Titer Determination (Focus Forming Assay)

- Serially dilute vector preparation 10-fold in culture medium

- Inoculate confluent cell monolayers in 96-well plates (100μL/well)

- Incubate 24-48 hours at 37°C, 5% CO₂

- Remove supernatant, wash cells 3× with PBS

- Fix with cold acetone (80% in water, 60 minutes, -20°C)

- Incubate with primary antibody (30 minutes, 37°C)

- Incubate with fluorescent secondary antibody (30 minutes, 37°C)

- Count fluorescent foci at appropriate dilution

Calculations:

- Genome/particle ratio = Vector genomes (qPCR) / Physical particles (EM)

- Infectious unit/particle ratio = FFU / Physical particles (EM)

- Particle/infectivity ratio = Physical particles (EM) / FFU

Quality Thresholds: For AAV vectors, genome/particle ratio should approach 1.0, with particle/infectivity ratio <100:1 for premium preparations.

The Scientist's Toolkit: Essential Research Reagents

Table 4: Key Reagents for High-Throughput Virology and Vector Development

| Reagent/Category | Specific Examples | Function/Application | Technical Notes |

|---|---|---|---|

| Viral Library Platforms | AAV capsid libraries, Lentiviral packaging systems | Diversity generation for vector optimization | Critical for tropism expansion and immune evasion |

| Cell Culture Systems | HEK293, Vero, BHK-21, C6/36, HmLu-1 [16] | Vector production and titration | Species and tissue origin affects viral replication |

| Molecular Kits | TRIZOL Reagent, QuantiTect Probe RT-PCR Kit [17] | Nucleic acid extraction and quantification | Essential for accurate genome counting |

| Quantitative Assays | qPCR, branched DNA, TaqMan systems [18] | Viral load and genome quantification | Varying sensitivity and reproducibility profiles |

| Detection Antibodies | Virus-specific primaries, fluorescent secondaries [17] | Infectivity quantification and visualization | Determines assay specificity and sensitivity |

| Sequencing Platforms | Illumina, Nanopore, PacBio | Vector integration and diversity analysis | Required for library selection tracking |

Integrated Development Pathway

The transition from rare disease research to mainstream applications follows a predictable pathway that integrates basic virology, clinical development, and commercial translation:

The synergy between rare disease therapeutics and high-throughput virology represents a powerful engine for biomedical innovation. Market forces, including substantial growth projections and regulatory incentives, combine with scientific advances in vector engineering and precision medicine to create an unprecedented opportunity for therapeutic development. The quantitative frameworks and standardized protocols presented herein provide researchers with essential tools for advancing this field. As viral vector technologies continue to evolve through high-throughput screening and engineering approaches, the transition from rare disease applications to mainstream medicine will accelerate, ultimately benefiting broader patient populations through platforms refined in rare disease contexts. This trajectory demonstrates how focused investigation of rare conditions can yield disruptive technologies with far-reaching medical implications.

The field of high-throughput virology (HTV) is undergoing a transformative shift, driven by the convergence of automation, miniaturization, and advanced analytics. This evolution is critical for supporting the rapidly expanding cell and gene therapy (CGT) pipeline, which includes over 2,000 candidates in development and relies heavily on viral vectors for delivery [19]. The global viral vector development market, valued at approximately $1 billion in 2025, is projected to grow at a compound annual growth rate (CAGR) of 15.11% to 18.84%, reaching up to $5 billion by 2034 [20] [21]. This growth is fueled by promising clinical results and increasing regulatory approvals for gene therapies and viral vector-based vaccines. However, the path from research to clinic is fraught with challenges, including complex manufacturing processes, high production costs, and difficulties in scaling [22] [19]. HTV platforms, integrating the core components of automation, miniaturization, and analytics, are designed to overcome these bottlenecks by enhancing process robustness, accelerating development timelines, and providing deep product characterization, thereby de-risking the journey from bench to bedside.

Core Component I: Automation in Viral Vector Production

Automation is a cornerstone of modern HTV platforms, directly addressing the critical challenges of scalability, reproducibility, and cost-efficiency that plague viral vector manufacturing.

Strategic Drivers for Automation

The adoption of automated systems is not merely a technical upgrade but a strategic necessity driven by several factors:

- Scalability Demands: As therapies progress from clinical trials to commercialization, manufacturing must scale up from small-scale research batches to large-volume commercial production. Automated bioreactor systems and downstream processing equipment are essential for this transition [19].

- Process Consistency and Reproducibility: Automated systems minimize human error and variability in complex, multi-step processes like transient transfection and downstream purification, ensuring batch-to-batch consistency [22].

- Reducing High Cost of Goods (COGs): Manual, labor-intensive processes, particularly in adherent cell culture systems for lentiviral vector production, contribute significantly to high COGs. Automation through fixed-bed bioreactors or automated suspension cultures reduces labor costs and improves efficiency [19].

Automated Upstream Processing

In upstream processing, automation enables precise control over critical process parameters. The shift from adherent culture in cell stacks to automated suspension-based bioreactors for AAV production represents a significant advancement [19]. For lentiviral vectors, which have traditionally relied on manual multilayer vessels, the implementation of fixed-bed bioreactor systems provides a closed, automated alternative that reduces contamination risk, lowers facility footprint, and enables more consistent vector yields [19].

Automated Analytics and High-Throughput Screening

Beyond production, automation is revolutionizing analytics. The development of a novel, high-throughput RNA-DNA hybrid capture-multiplex meso scale discovery (MSD) method for characterizing the integrity of the rAAV genome is a prime example. This automated method quantifies intact versus truncated genomes for both strands individually with high sensitivity and specificity, providing data that correlates strongly with rAAV activity [8]. Such automated analytical suites are vital for the rapid, data-driven decision-making required in HTV.

Table 1: Key Automated Systems in Viral Vector Manufacturing

| System Type | Application | Key Benefit | Example Technology |

|---|---|---|---|

| Fixed-Bed Bioreactor | Upstream LV Production | Closed, automated system; reduces labor & footprint | Single-use, automated fixed-bed bioreactors |

| Suspension Bioreactors | Upstream AAV Production | Scalable, closed system for commercial volumes | Stirred-tank or single-use bioreactors |

| Automated Purification & Filtration | Downstream Processing | Improves recovery rates & consistency | Tangential Flow Filtration (TFF) systems |

| Hybrid Capture-MSD Assay | rAAV Analytics | High-throughput genome integrity data | Automated MSD plate-based analyzer |

Core Component II: Miniaturization and High-Throughput Process Development

Miniaturization is a powerful paradigm that accelerates process development and optimization while conserving precious resources, acting as a bridge between benchtop research and large-scale GMP manufacturing.

The Rationale for Miniaturized HTV Platforms

The drive towards miniaturization is motivated by the "What to Test" trilemma, which highlights the difficulty in balancing physical fidelity, scalability/efficiency, and cost [23]. Miniaturized platforms address this by:

- Accelerating Experimental Timelines: They enable the parallel execution of hundreds of experiments in a short time, drastically speeding up the optimization of critical process parameters (CPPs) for both upstream and downstream operations.

- Dramatically Reducing Material Consumption: By working at the micro- or milliliter scale, these platforms minimize the consumption of expensive raw materials, such as plasmid DNA and cell culture media.

- Enhancing Data Density and Quality: Miniaturized systems allow for a more comprehensive exploration of the experimental design space, leading to robust and well-characterized processes.

Miniaturization in Analytical Method Development

The principles of miniaturization are also being applied to analytics. The high-throughput RNA-DNA hybrid capture MSD method is a key example, as it allows for the rapid characterization of numerous rAAV samples in parallel, providing crucial data on genome integrity that traditional viral genome titer assays lack [8]. This addresses a critical metrological gap in the field, moving beyond functional demonstration to rigorous, quantitative analysis [23].

A Miniature Mixed-Reality HIL Platform Case Study

The MMRHP (Miniature Mixed-Reality HIL Platform) exemplifies the integration of miniaturization with high-fidelity measurement. While developed for autonomous vehicles, its core principles are directly translatable to HTV for bioprocess optimization. The platform was designed to overcome the "How to Measure" dilemma by providing a systematic framework for auditable, quantitative, closed-loop evaluation [23]. Its key features include:

- A unified spatiotemporal measurement core ensuring consistent quantification.

- A stable closed-loop latency baseline and high spatial accuracy (10.27 mm RMSE).

- A structured, three-phase testing process for identifying performance limits and triggering conditions.

This approach underscores the value of miniaturized, data-rich systems for diagnosing process performance and establishing known, controllable operating boundaries—a fundamental requirement for robust viral vector manufacturing.

Core Component III: Advanced Analytics for Vector Characterization

Advanced analytics form the decision-making backbone of any HTV platform, providing the deep product and process understanding required for regulatory compliance and process control.

Moving Beyond Traditional Titer Assays

While viral genome (Vg) titer is a standard potency measure for rAAV, it is an insufficient metric alone. The rAAV genome is a heterogeneous population containing both intact genomes and numerous truncated species that lack functionality [8]. This disconnect between Vg titer and biological activity necessitates more sophisticated analytical methods to fully characterize product quality.

Genome Integrity Analysis

A novel RNA-DNA hybrid capture-multiplex Meso Scale Discovery (MSD) method has been developed to directly address the limitation of Vg titer. This method specifically quantifies the intact versus truncated genomes of both the plus and minus strands individually with high sensitivity and specificity [8]. The data generated shows a strong correlation with rAAV activity, making it a superior tool for assessing true product potency, optimizing vector design, and improving delivery efficiency.

The Essential "Scientist's Toolkit"

Successful implementation of an HTV platform relies on a suite of specialized research reagents and tools. The table below details key components essential for viral vector process development and analytics.

Table 2: Research Reagent Solutions for High-Throughput Virology

| Reagent/Material | Function in HTV | Application Example |

|---|---|---|

| HEK293 Cell Line & Derivatives | Robust, widely adopted host cell for AAV, Adenovirus, and Lentivirus production [22]. | Adherent or suspension culture in scale-down bioreactor models. |

| Synthetic DNA | Scalable alternative to plasmid DNA; eliminates bacterial contaminants, shortens timelines, reduces costs [19]. | Transient transfection in high-throughput micro-bioreactors. |

| Stable Producer Cell Lines | Engineered cells that stably express viral components, eliminating the need for transfection and its variability [19]. | AAV or LV production in a standardized, high-yield platform process. |

| RNA-DNA Hybrid Capture Probes | Target-specific capture of intact rAAV genomes for precise quantification of full-length vs. truncated species [8]. | High-throughput integrity analysis via multiplex MSD assays. |

| Multiplex MSD Electrochemiluminescence Tags | Enable simultaneous, quantitative detection of multiple analytes (e.g., plus and minus strands) with high sensitivity [8]. | High-throughput potency and integrity profiling of rAAV samples. |

Integrated Experimental Protocols

This section provides a detailed methodology for a key experiment that integrates the three core HTV components to optimize and characterize a viral vector production process.

Protocol: High-Throughput Screening of Transfection Conditions for rAAV Production in a Miniaturized System

1. Objective: To systematically screen transfection parameters (e.g., DNA:PEI ratio, cell density, harvest time) in a high-throughput, miniaturized bioreactor system to identify conditions that maximize the yield of full-length, functional rAAV vectors.

2. Experimental Workflow: The following diagram illustrates the integrated workflow for this high-throughput screening protocol.

3. Materials:

- Cells: HEK293 suspension cells.

- Plasmids: pHelper, pRep/Cap, pITR-transgene (or synthetic DNA alternatives).

- Transfection Reagent: Linear PEI.

- Equipment: Automated micro-bioreactor system (e.g., ambr 250 or 15), liquid handling robot, analytical instruments (qPCR, MSD, HPLC).

- Consumables: Deep-well plates, micro-bioreactor vessels.

4. Procedure: 1. Cell Inoculation: Using an automated liquid handler, inoculate HEK293 suspension cells into an array of micro-bioreactors to a pre-determined viable cell density (VCD). Allow cells to adapt under controlled conditions (temperature, pH, DO, agitation). 2. Design of Experiment (DoE) Execution: Program the liquid handler to execute a pre-defined DoE. This will involve transferring different volumes of DNA and PEI solutions to deep-well plates, allowing complex formation, and subsequently delivering these complexes to the individual micro-bioreactors. 3. Process Monitoring: Allow the transfections to proceed with continuous monitoring and control of CPPs. Feed additions or pH adjustments can be automated. 4. Automated Harvest: At defined timepoints post-transfection, trigger an automated harvest sequence. This may involve transferring the culture contents to a separate plate for primary clarification via centrifugation or filtration. 5. High-Throughput Analytics: - Total Vector Genome Titer: Use a automated, plate-based qPCR or ddPCR assay to determine the total Vg titer for each condition. - Genome Integrity: Apply the RNA-DNA hybrid capture-MSD method to a lysed aliquot from each condition to determine the percentage of full-length, intact genomes [8]. - Infectivity/Potency: If applicable, perform a high-throughput cell-based assay (e.g., using a reporter cell line in a plate format) to assess functional titer. 6. Data Analysis and Modeling: Integrate all data (process parameters, Vg titer, % full-length, potency) into a statistical software package. Build multivariate models to identify the CPPs that most significantly impact both the yield and quality of the rAAV product.

5. Key Outputs:

- A ranked list of transfection conditions based on a combined metric of yield and quality.

- A predictive model showing the relationship between CPPs and Critical Quality Attributes (CQAs).

- A scalable, optimized process ready for verification in a larger bioreactor system.

The synergistic integration of automation, miniaturization, and advanced analytics is no longer a future aspiration but a present-day imperative for advancing viral vector production. These core HTV components directly address the pressing commercial challenges of high COGs, manufacturing complexity, and limited scalability that threaten to constrain the promise of cell and gene therapies [19]. By enabling rapid, data-driven process development, ensuring robust product characterization, and providing a clear path to scalable manufacturing, HTV platforms are de-risking the entire development pathway. As the industry moves towards more standardized, platform-based manufacturing processes and embraces novel technologies like synthetic biology and AI-powered analytics, the role of these integrated HTV components will only become more central. Their continued evolution is essential for translating the remarkable scientific progress in gene therapy into scalable, affordable, and accessible medicines for patients worldwide.

Advanced HTV Workflows: From Robotic Automation to AI-Driven Optimization

The growing demand for viral vectors in gene therapy and vaccinology necessitates the development of robust, scalable, and efficient production platforms [24]. High-Throughput Virology (HTV) platforms address this need by integrating advanced robotic automation with systematic experimental methodologies. The combination of Design of Experiments (DoE) with robotic liquid handling creates a powerful framework for accelerating process optimization in viral vector production [25]. This approach enables researchers to efficiently explore complex parameter spaces, optimize critical process parameters, and enhance product quality and yield while significantly reducing development timelines and costs.

The global market for viral vector production for research use is projected to grow from $1.9 billion in 2025 to $7.3 billion by 2035, representing a compound annual growth rate of 14.4% [24]. This expansion is largely driven by increasing demand for gene therapy research tools and the need for high-quality viral vectors in biomedical applications. Similarly, the automated liquid handling systems market is expected to grow from $3.26 billion in 2025 to $6.35 billion by 2035, with a CAGR of 6.9% [26]. This parallel growth underscores the interdependence of these technologies in advancing virology research.

Robotic Liquid Handling Systems

Robotic liquid handling systems, also known as automated liquid handling workstations, are sophisticated laboratory automation systems designed to precisely dispense liquids in pharmaceutical and biochemical applications [27]. These systems consist of several key components: sampling mechanisms, distribution modules, detection units, and software controls. By automating repetitive pipetting tasks, they enhance workflow efficiency while reducing human error and contamination risks in processes like high-throughput screening, PCR setup, and cell-based assays [27].

Table 1: Robotic Liquid Handling System Specifications

| Parameter | Options | Applications |

|---|---|---|

| Pipetting Technology | Air displacement, Piston/Positive displacement, Acoustic, Free-jet [26] | High-throughput screening, PCR setup, serial dilution [26] |

| Modality | Fixed tips, Disposable tips [26] | Cell culture, bead washing, plate replication [26] |

| Instrument Type | Standalone, Individual benchtop workstation, Multi-instrument systems [26] | Genomics, proteomics, clinical diagnostics [28] |

| Throughput | Single, 8-channel, 12-channel, 24-channel, Other multichannel [28] | Drug discovery, biopharmaceutical R&D [27] |

The global robotic liquid handling equipment market was valued at $1,155 million in 2024 and is projected to reach $1,774 million by 2032, exhibiting a CAGR of 6.5% during this period [27]. This growth is fueled by increasing demands for high-throughput screening in drug discovery, where these systems can reduce screening times by over 40% while improving accuracy and reproducibility [27].

Design of Experiments (DoE) in Virology

DoE represents a systematic approach to investigation that allows for the efficient exploration of process parameters and their interactions. In virology applications, DoE enables researchers to understand the complex relationships between critical process parameters and key quality attributes of viral vectors. The application of DoE is particularly valuable in chromatography optimization, where parameters such as loading density, pH, and residence time can significantly impact product quality and yield [25].

Recent advancements have demonstrated that High-Throughput Process Development (HTPD) combined with DoE methodologies can revolutionize AAV process optimization, creating streamlined, adaptable approaches tailored to diverse serotypes and product profiles [25]. These advanced tools reduce time-to-clinic while elevating quality and yield for gene therapy candidates.

Integrated Platform Configuration

System Components and Integration

The integrated HTV platform combines robotic liquid handling systems with DoE software and specialized analytics to create a comprehensive optimization workflow. Modern systems incorporate advanced features such as barcode identification for tracking sample reagents, temperature control modules, and liquid level sensors for enhanced precision and workflow management [26]. Modular designs allow for customization to meet specific laboratory requirements, with software advancements enabling seamless integration with Laboratory Information Management Systems (LIMS) and other laboratory instruments [28].

A key advancement in this field is the development of flexible workstation configurations, with modular platforms now representing over 40% of new installations [27]. These systems allow laboratories to adapt hardware configurations based on changing research needs – from basic liquid transfers to integrated processes combining dispensing, heating, and shaking. The emergence of collaborative robotics (cobots) in lab environments further supports this trend, enabling safe human-robot interaction during complex protocols [27].

Table 2: Key Platform Components for Viral Vector Production

| Component | Function | Example Specifications |

|---|---|---|

| Robotic Liquid Handler | Precise reagent dispensing and sample preparation | 384-well format, 5-fold reduced reaction volume [29] |

| DoE Software | Experimental design and data analysis | Capable of evaluating 17+ conditions simultaneously [25] |

| Analytics Suite | Quality assessment and process monitoring | MADLS, ELISA for capsid quality and titer [25] |

| Microplate Washer | Bead washing and plate processing | Compatible with flat microplates, ultrasonic/acoustic/centrifugal technology [26] |

Workflow Automation

The integration of robotic automation with DoE principles enables the complete automation of complex experimental workflows. Modern systems can integrate a cap-decapper, semi-automatic sample addition and dilution, and a microplate stacker with automated imaging to reduce hands-on time [29]. This level of automation is particularly valuable in high-throughput neutralization assays, where automated 384-well methods have demonstrated strong concordance with conventional 96-well methods while increasing daily sample throughput by approximately 6.7-fold [29].

The automation of viral vector production workflows follows a systematic process that begins with experimental design and proceeds through automated execution to final analysis. This workflow can be visualized as follows:

This continuous improvement cycle enables rapid optimization of viral vector production processes, with each iteration building upon insights gained from previous experiments.

Application Notes: AAV Manufacturing Case Study

Process Optimization

In a recent case study, the integration of HTPD and DoE methodologies enabled significant advances in AAV process optimization [25]. Researchers employed a flexible, modular downstream process featuring depth filtration, capture and polishing chromatography, and sterile formulation. By integrating robotic automation (e.g., Biomek i7), they could evaluate up to 17 experimental conditions simultaneously, enabling rapid, resource-efficient decisions [25].

Through in-depth statistical DoE assessments, researchers identified that loading density strongly influences AAV products' monomer content and capsid yield. Specifically, higher loading density resulted in higher monomer content (as measured by dynamic light scattering), while lower loading density led to greater capsid recovery (as quantified by ELISA) [25]. Interestingly, parameters such as pH and residence time were found to have minimal impact on yield in this specific system. This discovery enabled more precise capture chromatography control, leading to faster iteration and reduced development cost while ensuring consistency.

Quality and Yield Enhancement

The integrated HTV platform supported significant improvements in critical quality parameters for AAV vectors. The approach enabled:

- Scalable, GMP-compliant plasmid production

- Reduced vector impurities and aggregation

- Enhanced capsid quality for therapeutic-grade AAVs [25]

These quality improvements are particularly important given the stringent requirements for viral vectors used in gene therapy applications. The integration of advanced analytics like multi-angle dynamic light scattering (MADLS) and ELISA within the HTV platform provides comprehensive characterization capabilities that support the development of robust, clinical-grade vector production processes [25].

Detailed Experimental Protocols

Protocol 1: High-Throughput Screening of Chromatography Conditions

Objective: To systematically evaluate the effect of multiple chromatography parameters on AAV vector quality and yield using DoE and robotic liquid handling.

Materials and Equipment:

- Robotic liquid handling workstation (e.g., Biomek i7, Tecan Veya, Hamilton Robotics system)

- 96-well or 384-well chromatography plates

- AAV lysate

- Binding and elution buffers at varying pH and conductivity

- ELISA kits for capsid titer determination

- MADLS instrumentation for aggregation assessment

Procedure:

- DoE Setup: Using statistical software, design an experiment examining 3-5 factors (e.g., loading density, pH, conductivity, residence time, temperature) with 3-5 levels each. A fractional factorial design can reduce the number of conditions while maintaining statistical power.

- Buffer Preparation: Program the liquid handler to prepare binding and elution buffers according to the experimental design. The system should precisely dispense buffer components to achieve the desired pH and conductivity conditions.

- Plate Preparation: The robotic system should aliquot chromatography resin into a 96-well filter plate, with consistent bed volume across all wells.

- Equilibration: Program methods for equilibration with appropriate binding buffer for each condition.

- Loading: Precisely load AAV lysate according to the designated loading densities specified in the experimental design.

- Washing: Execute wash steps with binding buffer.

- Elution: Perform elution with the predetermined buffer conditions for each well.

- Collection: Transfer eluates to a collection plate for analysis.

- Analysis: Automatically transfer aliquots to analytics platforms for capsid titer (ELISA), purity (HPLC), and aggregation (MADLS) assessment.

Table 3: Experimental Parameters and Ranges for AAV Chromatography Screening

| Parameter | Low Level | Middle Level | High Level |

|---|---|---|---|

| Loading Density (vg/mL resin) | 1.0 × 10^12 | 3.0 × 10^12 | 1.0 × 10^13 |

| Binding pH | 6.5 | 7.2 | 8.0 |

| Binding Conductivity (mS/cm) | 5 | 10 | 20 |

| Residence Time (min) | 2 | 5 | 10 |

| Elution pH Step | 0.5 | 1.0 | 1.5 |

Protocol 2: Automated Viral Vector Neutralization Assay

Objective: To implement a high-throughput pseudovirion-based neutralization assay (PBNA) for evaluating neutralizing antibodies against multiple viral types.

Materials and Equipment:

- Automated liquid handling system (e.g., INTEGRA ASSIST PLUS, VIAFLO)

- 384-well cell culture plates

- 293FT cells

- Pseudotyped viruses

- Serum samples

- Fluorescence detection system (e.g., Biotek Cytation 5)

Procedure:

- Sample Preparation: Using the automated cap-decapper and pipetting workstation, prepare serum samples in 96-well U-bottom plates with serial dilutions.

- Virus Addition: Program the liquid handler to add pseudotyped viruses to the serum samples.

- Incubation: Incubate virus-serum mixtures at 4°C for 1 hour.

- Cell Seeding: Automatically seed 293FT cells (3 × 10^3 cells in 20 μL) into 384-well plates.

- Mixture Transfer: Transfer the virus-serum mixture to the cell plates.

- Culture: Incubate at 37°C with 5% CO2 for 60-96 hours.

- Detection: Quantify fluorescent spots using an automated imaging system.

- Analysis: Calculate neutralizing titers based on fluorescent counts [29].

This automated 384-well method has demonstrated strong concordance with conventional 96-well PBNA while increasing daily sample throughput by approximately 6.7-fold and reducing reaction volume by approximately 5-fold [29].

The Scientist's Toolkit

Table 4: Essential Research Reagent Solutions for HTV Platforms

| Reagent/Consumable | Function | Application Notes |

|---|---|---|

| Adeno-associated Viral (AAV) Vectors | Gene delivery vehicles | Account for 39.0% of viral vector production market due to superior safety characteristics [24] |

| Lentiviral Vectors | Stable gene integration | Represent 28.0% of viral vector demand; ideal for applications requiring long-term expression [24] |

| Pseudotyped Viruses | Neutralization assays | Enable safe evaluation of neutralizing antibodies without handling pathogenic viruses [29] |

| Chromatography Resins | AAV purification | Selection critical for optimizing capsid recovery and monomer content [25] |

| ELISA Kits | Capsid titer quantification | Essential for determining viral vector concentrations throughout process optimization [25] |

| MADLS Consumables | Aggregation analysis | Critical for assessing product quality and vector integrity [25] |

Data Analysis and Interpretation

DoE Results and Modeling

The application of DoE in viral vector production generates complex multivariate datasets that require specialized statistical analysis. Response surface methodology and predictive modeling are particularly valuable for identifying optimal process conditions and understanding parameter interactions.

In chromatographic optimization for AAV production, DoE assessments have revealed that loading density strongly influences critical quality attributes. Higher loading density correlates with increased monomer content, while lower loading density enhances capsid recovery [25]. Predictive models generated from DoE data enable researchers to confirm optimal conditions experimentally, leading to more precise process control.

The relationship between experimental factors and process outcomes can be visualized as follows:

Quality Control and Analytics

Integrated HTV platforms rely on advanced analytical techniques to assess product quality and process performance. Key analytical methods include:

- Multi-angle Dynamic Light Scattering (MADLS): Provides comprehensive characterization of vector size distribution and aggregation state [25]

- ELISA: Quantifies capsid titer and assesses vector concentration [25]

- PCR-based methods: Determine genomic titer and assess vector potency

- Next-generation sequencing: Evaluates vector integrity and identifies contaminants

These analytical methods are increasingly being automated and integrated with the liquid handling platforms to enable real-time quality assessment and process control.

The integration of DoE methodologies with robotic liquid handling systems creates a powerful platform for accelerating viral vector process development. This approach enables researchers to efficiently explore complex parameter spaces, optimize critical process parameters, and enhance product quality and yield while significantly reducing development timelines. As the viral vector production market continues its rapid growth – projected to reach $7.3 billion by 2035 [24] – these integrated platforms will play an increasingly important role in translating gene therapy research into clinical applications.

The continued advancement of HTV platforms, including the integration of artificial intelligence for predictive modeling and the development of more modular, flexible automation systems, will further enhance their capabilities. These technological improvements will support the growing demand for viral vectors in gene therapy, vaccinology, and other biomedical applications, ultimately accelerating the development of novel treatments for genetic disorders, cancer, and infectious diseases.

The production of viral vectors and vaccines represents a critical bottleneck in modern therapeutics and immunology. Traditional methods for optimizing these complex bioprocesses are often slow, resource-intensive, and limited in their ability to navigate high-dimensional parameter spaces. The integration of Bayesian optimization (BO) and machine learning (ML) algorithms presents a paradigm shift, enabling rapid, data-driven optimization of biological systems. This approach is particularly valuable in high-throughput virology research, where it accelerates development timelines while improving product yields and quality. By implementing iterative cycles of machine learning prediction and experimental validation, researchers can now optimize systems with dozens of critical parameters simultaneously, dramatically reducing the experimental burden compared to traditional methods such as one-factor-at-a-time (OFAT) or Design of Experiments (DoE) approaches [30]. This document provides detailed application notes and protocols for implementing these algorithmic approaches within virology and vector production research settings.

Key Applications in Virology and Vector Production

The application of Bayesian and machine learning optimization has yielded substantial improvements across multiple domains of virology research and production. The following case studies demonstrate the quantitative benefits achieved through these approaches.

Table 1: Algorithmic Optimization Applications in Virology

| Application Area | Optimization Approach | Key Parameters Optimized | Documented Improvement |

|---|---|---|---|

| mRNA Vaccine Production (SARS-CoV-2) | Bayesian Optimization [31] [32] | 11 IVT process parameters | 12% yield improvement, 50% reduction in reaction time, 44% reduction in expensive reagent use [31] |

| Viral Vaccine Formulation | Bayesian Optimization [33] | Excipient combinations for stability | Improved stability prediction (R² > 0.9) for live-attenuated viruses [33] |

| Cell Culture Media Development | Bayesian Optimization [30] | Media components with categorical and continuous variables | 3-30x fewer experiments required vs. traditional DoE [30] |

| AAV Vector Development | Directed Evolution & Computational Modeling [15] | Capsid engineering, genome regulation | Accelerated selection of human-optimized AAV variants [15] |

| Plant-Based Biopharmaceutical Production | Bayesian Experimental Design [34] | Macronutrient concentrations (sucrose, ammonium, nitrate, phosphate) | 36% improvement in biomass productivity [34] |

Bayesian Optimization Protocol for In Vitro Transcription (IVT) Reaction Enhancement

Background and Principles

In vitro transcription (IVT) reactions for mRNA vaccine production involve complex interactions between multiple component concentrations, enzymatic activity, and reaction conditions. Bayesian optimization provides a powerful framework for navigating this high-dimensional parameter space efficiently. The protocol below outlines a standardized method for implementing BO to enhance IVT processes for viral vaccine production, adapting methodology proven successful in optimizing SARS-CoV-2 mRNA vaccine production [31] [32].

Experimental Protocol

Preliminary Experimental Setup

- Objective Definition: Clearly define primary optimization objectives (e.g., maximize mRNA yield, percent intact mRNA, or minimize reaction time, reagent consumption).

- Parameter Selection: Identify critical process parameters to optimize. For IVT, these typically include:

- Nucleotide triphosphate (NTP) concentrations

- Magnesium ion (Mg²⁺) concentration

- DNA template concentration

- T7 RNA polymerase concentration and type

- Incubation temperature and duration

- Buffer composition and pH

- Constraint Establishment: Define feasible ranges for each parameter based on biochemical constraints and preliminary data.

Initial Design of Experiments

- Space-Filling Design: Generate an initial set of 10-20 experiments using Latin Hypercube Sampling or similar space-filling design to ensure good coverage of the parameter space.

- Experimental Execution: Perform IVT reactions according to the initial design.

- mRNA Quantification: Measure mRNA yield using spectrophotometric or fluorometric methods.

- Quality Assessment: Analyze mRNA integrity via capillary electrophoresis or gel analysis.

- Data Collection: Record all response variables for each experimental condition.

Iterative Optimization Phase

- Model Training: Employ a Gaussian Process (GP) as a probabilistic surrogate model to capture the relationship between process parameters and outcomes.

- Acquisition Function: Use an acquisition function (Expected Improvement is recommended) to identify the most promising experimental conditions for the next iteration.

- Parallel Experimentation: Conduct 4-8 parallel experiments per iteration based on algorithm recommendations.

- Model Updating: Incorporate new experimental results to refine the GP model after each iteration.

- Stopping Criteria: Continue iterations until performance plateaus or reaches target thresholds (typically 5-8 iterations).

Validation

- Confirmatory Experiments: Perform triplicate validation runs using the optimized parameters.

- Benchmarking: Compare optimized conditions against baseline performance using standardized metrics.

Expected Outcomes

Implementation of this protocol should yield significant improvements in IVT performance. Published results demonstrate achievement of 12% yield improvement with 50% reduction in reaction time, while reducing consumption of expensive reagents by up to 44% [31]. Final conditions produced 12 g·L⁻¹ of mRNA in just 2 hours in one application [32].

Workflow Diagram: Bayesian Optimization for Virology Applications

The following diagram illustrates the iterative workflow for Bayesian optimization in virology applications:

High-Through Sequencing for Viral Detection and Characterization

Background

High-Throughput Sequencing (HTS) has become an indispensable tool in virology for adventitious virus detection, viral vector characterization, and virome analysis. When combined with machine learning approaches, HTS enables comprehensive viral safety assessment and discovery. The following protocol outlines a standardized approach for virus detection using short-read HTS in samples with high virus titer and low cellular background, relevant for viral vector and vaccine production [9].

Experimental Protocol

Sample Preparation and Nucleic Acid Extraction

- Sample Input: Use purified viral samples (e.g., adenovirus vector preparation) at 1-5 × 10⁹ genome copies/mL.

- Nucleic Acid Extraction: Employ validated extraction kits that preserve both DNA and RNA viruses.

- Recommended: Combined DNA/RNA extraction protocols or separate extractions followed by pooling.

- Inhibition Control: Include spike-in controls to monitor extraction efficiency.

- Nucleic Acid Quantification: Use fluorometric methods for accurate concentration measurement.

Library Preparation and Sequencing

- Whole Transcriptome Amplification: Implement random amplification approaches to ensure detection of unknown viruses.

- Library Construction: Use Illumina-compatible library preparation kits with dual index barcoding.

- Fragment Size: Target 200-500bp insert size.

- PCR Cycles: Minimize amplification cycles to reduce bias (typically 8-12 cycles).

- Quality Control: Assess library quality using capillary electrophoresis.

- Sequencing: Perform Illumina sequencing (2×150bp or 2×250bp) with sufficient depth (>10 million reads per sample).

Bioinformatic Analysis

- Quality Control and Filtering:

- Use FastQC for initial quality assessment.

- Perform adapter trimming and quality filtering with Trimmomatic or similar tools.

- Host Sequence Removal:

- Align reads to host genome (e.g., human, hamster) using BWA or Bowtie2.

- Retain unmapped reads for viral analysis.

- Viral Detection:

- Targeted Analysis: Map reads to reference genomes of expected viruses.

- Non-Targeted Analysis: Align reads to comprehensive viral databases (RVDB).

- Virus Identification:

- Apply minimum threshold of 10-50 reads mapping to viral genome.

- Require coverage across >5% of genome length.

- Use BLAST for confirmation of novel viruses.

Sensitivity Assessment

- Limit of Detection: Establish detection sensitivity using spiked reference viruses.

- Validation: Demonstrate detection of 10⁴ genome copies/mL for diverse virus types [9].

Expected Outcomes

Proper implementation should enable detection of diverse viruses including Epstein-Barr virus (EBV), feline leukemia virus (FeLV), respiratory syncytial virus (RSV), mammalian orthoreovirus type 1 (Reo1), and porcine circovirus type 1 (PCV1) at concentrations of 10⁴ GC/mL or lower, with some laboratories achieving detection at 10²-10³ GC/mL through protocol optimization [9].

The Scientist's Toolkit: Essential Research Reagents and Platforms

Table 2: Key Research Reagent Solutions for Algorithmic Optimization in Virology

| Reagent/Platform | Function | Application Notes |

|---|---|---|

| T7 RNA Polymerase | Catalyzes in vitro transcription of mRNA | Commercial variants differ in performance; automated screening recommended post-optimization [31] |

| CBER NGS Virus Reagents | Reference standards for HTS validation | Includes EBV, FeLV, RSV, Reo1, PCV1; enables sensitivity determination [9] |

| Gaussian Process Modeling | Probabilistic surrogate model for BO | Particularly suited for noisy biological data with small sample sizes [30] |

| Illumina Short-Read Sequencing | High-throughput viral detection | Enables identification of known and novel viruses without prior sequence knowledge [9] |

| Reference Viral Database (RVDB) | Comprehensive viral sequence database | Essential for non-targeted bioinformatic analysis of HTS data [9] |

| Automated Liquid Handling | High-throughput experimental execution | Enables rapid iteration of Bayesian optimization experimental cycles [31] |

| Bayesian Optimization Software | Algorithmic experimental design | Custom Python implementations or commercial platforms (e.g., Ax, BoTorch) |

Workflow Diagram: High-Throughput Sequencing for Viral Safety

The following diagram illustrates the integrated workflow for viral safety testing using high-throughput sequencing:

Implementation Considerations for Research Programs

Resource Planning and Experimental Design

Successful implementation of algorithmic optimization approaches requires careful resource planning. Bayesian optimization methods typically require 40-60 total experiments to optimize 10-15 parameters, representing a 3-30x reduction in experimental burden compared to traditional DoE approaches [30]. Research programs should allocate resources for:

- Initial Screening Experiments: 10-20 experiments for initial space-filling design

- Iterative Optimization: 4-8 experiments per iteration for 5-8 iterations

- Validation Studies: 5-10 confirmatory experiments

Integration with High-Throughput Platforms

The efficiency of algorithmic optimization is maximized when integrated with automated high-throughput systems:

- Liquid Handling Robots: Enable rapid execution of iterative experimental designs

- Automated Analytics: High-throughput quantification methods (spectrophotometry, capillary electrophoresis)

- Data Management Systems: Structured data capture for seamless model updating

Computational Infrastructure

Adequate computational resources are essential for implementing these approaches:

- Hardware: Multi-core processors for Gaussian process modeling and HTS data analysis

- Software: Python ecosystem (scikit-learn, GPy, BoTorch) for Bayesian optimization

- Bioinformatics: High-performance computing resources for HTS analysis